11

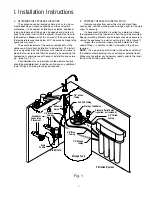

O. APPENDIX FOR BASEMENT INSTALLATIONS

The following variations are generally required for basement

installations:

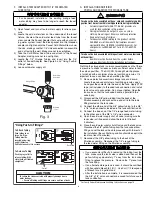

INSTALL THE DRAIN CONNECTION

For basement installations, the drain saddle is generally

not used. Instead, the RO reject line (SFC tubing) is routed

so that it drains into a laundry sink, floor drain, or standpipe

through an approved air gap.

MOUNT THE FAUCET

If you choose to use the air gap faucet included with the

RO system, follow the faucet installation instructions given ear-

lier in this manual. Do not hook up any air gap tubing to the

faucet since an alternate air gap will be used elsewhere in the

drain line.

If you choose to use the optional non-air gap faucet, follow

the instructions below.

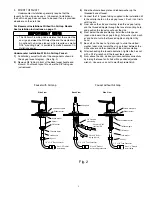

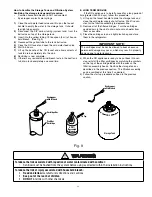

A) Familiarize yourself with all of the components shown in

the diagram of the non-air gap faucet. (See Fig. 2)

B) Install only the chrome base plate and rubber sealing washer

onto the threaded nipple. (Plumbers’ putty may be used in

place of the sealing washer for a neater appearance.)

C) Feed the threaded nipple through the sink/countertop

mounting hole (a 9/16” hole is adequate).

D) From underneath the sink/countertop, install the plastic

bottom washer, flat washer, star washer, and hex nut onto

the threaded nipple. Hand tighten the hex nut until the

faucet feels snug.

E) After rechecking the faucet orientation, tighten the hex nut

with at 9/16” wrench until the faucet feels secure.

F) From above the sink, make any minor orientation

corrections by turning the faucet on its “flats” with a

padded adjustable wrench. Use care so as not to mar the

chrome finish.

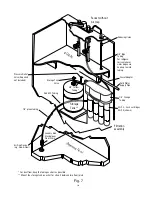

INSTALL THE FILTRATION ASSEMBLY AND THE

STORAGE TANK

The filtration assembly is generally mounted to the basement

wall (using wall anchors) or to the wood ceiling supports. To

mount the filtration assembly, keep the bracket level and mark the

location of the mounting holes. Install wall anchors and/or mount-

ing screws as required. Leave the screw heads protruding to

allow the bracket mounting slots to slide over them. (See Fig. 7)

The tank may be oriented either vertically or horizontally and

can be placed on a shelf, on the floor, or suspended from the ceil-

ing supports using brackets.

An effort should be made to minimize the distance between

the tank and filtration assembly in order to ensure an adequate

flow rate to the faucet.

MAKE THE TUBING CONNECTIONS

1) A proper length of the 1/4” orange feed water tubing

should already have been connected to the cold water

supply shut off valve. Route it through the large opening

in the bottom of the metal bracket and loop it back to the

“FEED” connection on the filtration assembly.

2) Connect a longer length of 3/8” blue tubing (not included) to

the faucet adapter. Route the tubing through the floor to the

location of the filtration assembly. Remove the existing

3/8” blue tubing from the filtration assembly. Route the

other end of the longer length of 3/8” blue tubing through the

large opening in the bottom of the metal bracket and connect

it to the “FAUCET” connection on the filtration assembly.

NOTE: Instead of removing the existing 3/8” blue tubing from

the filtration assembly, a 3/8” connector fitting can be used to

join the tubing from the faucet with the tubing from the filtration

assembly.

3) Route the 3/8” yellow tubing from the filtration assembly

to the storage tank.

4) Route 1/4” tubing from an appropriate drain connection

(e.g. laundry sink, floor drain, standpipe) to the location of

the filtration assembly. An air gap must be provided

between the outlet and the drain connection.

5) Connect the red SFC tubing from the filtration assembly

to the 14” tubing from the drain connection using the 1/4”

connector fitting on the end of the SFC tubing.