P. INSTALLATION TROUBLESHOOTING

Problem: Leak at the drain saddle.

Possible Cause: Drain saddle not clamped tightly enough.

Solution: Tighten the drain saddle screws evenly and firmly.

Problem: Leak at the fittings threaded connection.

Possible Cause: Fitting is improperly taped or not `

tightened sufficiently.

Solution: Retape the threaded portion with PTFE tape and

thread it in firmly. Do not over tighten.

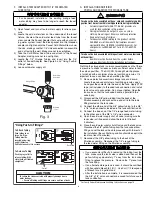

Problem: Leak at the fitting’s push-in connection.

Possible Cause: Tubing is damaged if there is a tubing mis-

assembly.

Solution: Remove the tubing. Squarely cut off 1/4 inch from

the end of the tubing using a sharp razor knife and reinsert it

into the fitting. Make sure that the tubing is pushed in com-

pletely until it seats.

Problem: Leak at the filter cartridge head.

Possible Cause: Damaged or misaligned O-ring.

Solution: Close the cold water supply shut off valve and the

storage tank valve. Lift up on the faucet handle and drain the

tank a minimum of 5 minutes. Remove the filter cartridge and

check the condition of the O-rings. If they are misaligned,

reseal them. If they are damaged, replace them.

Problem: The faucet leaks from the spout with the handle down.

Possible Cause: An obstructed or damaged valve seat in the

faucet mechanism.

Solution: Remove the faucet spout with a twisting/lifting

motion and slide the faucet handle forward over the spout

hole to gain access to the faucet valve. Unscrew the tee-bar

and the slotted bushing to remove the valve. Clean out any

obstruction or replace it with a new valve mechanism if neces-

sary.

Problem: No steady drip from the open faucet after the

tank is drained.

Possible Causes:

•

The cold water supply shut off valve is not open.

•

A leak from any product water fitting connection.

•

The icemaker valve was left open before the start-up

procedure completed.

•

Air is still trapped in the system.

Solutions:

•

Open the cold water supply shut off valve completely.

•

Correct the fitting leak as outlined above.

•

Close the icemaker valve and wait until the faucet drips.

•

Wait for the air to be purged from the system.

Problem: Water leaks from air gap module opening.

Possible Causes:

•

The drain line tubing is looped, kinked, or has a low spot.

•

The drain line is blocked or the drain hole is not drilled

through completely.

•

Air is locked in the air gap outlet.

•

There is excessive RO reject flow.

Solutions:

•

Trim any excess tubing to obtain a short, “straight-shot” to

the drain.

•

Check to see that the drain line is clear of any obstruction

and remove the drain saddle fitting to verify that the hole is

drilled through completely.

•

Blow air into the air gap outlet using a short length of tubing.

•

Disconnect the red SFC reject tubing from the faucet air

gap inlet tubing and check the reject flow rate. It should

be less than 5.9 ounces/min. If it is greater than 5.9 ounc

es/min, replace the red SFC reject tubing with the new one

of proper length.

Problem: Too little or no reject flow.

Possible Causes:

•

Red SFC reject tubing is plugged or damaged.

•

An obstruction in the faucet air gap module.

Solutions:

•

Replace the SFC reject tubing with one of proper length.

•

Remove the air gap module and inspect the internal flow

path. Replace the air gap module if necessary.

Problem: Chlorine or other unpleasant taste/odor is evi-

dent after the initial tank filling.

Possible Cause: Residual preservative/sanitizer is still in the

water.

Solution: Drain and fill the storage tank several times if

necessary.

Problem: Noise in the drain (gurgling or

dribbling sound).

Possible Cause: The reject water is dripping into the standing

water in the drain trap.

Solutions:

•

Make sure that the 3/8” black drain tubing from the faucet

air gap module slopes continuously downward to the drain

saddle without any loops or low spots.

•

Angle the drain piping so that the reject water runs down

the side of the drain pipe.

•

Change the location of the drain saddle to the horizontal

drain pipe or any alternate vertical drain pipe which is

farther from the trap. Properly plug the original hole.

•

Drill larger hole in drain pipe.

Caution: Make sure the drain saddle is always installed

above (before) the trap.

12