How to Replace the RO Membrane Cartridge

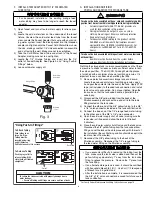

1) Close the cold water supply shut off valve. Lift up on the

faucet handle to drain the tank. Wait five (5) minutes for

the filtration assembly to completely depressurize.

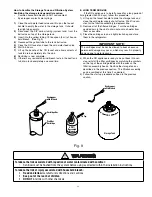

2) Make sure that there is some slack in the red SFC tubing

connected to the fitting at the bottom of the RO membrane

cartridge. Twist the cartridge 1/4 turn clockwise so that

the tubing connection is accessible. (See Fig. 8)

3) Remove the red SFC tubing by depressing the small gray

collet and pulling the tubing away from the fitting.

Note: It is advisable to check the end of the red SFC tubing

for nicks or scratches. If any are observed, cut off 1/4” from

the end of the tubing with a sharp razor knife.

4) Firmly pull the cartridge away from the head. (It may be

necessary to twist the cartridge slightly from side to side.)

5) Remove the new RO membrane cartridge from its sanitary

sealed wrapper. (Double check to see that it is the correct

replacement by comparing the labels.) Rinse it with tap

water and dry it off.

6) Remove the white plug from the fitting at the bottom of the

cartridge by pushing in the small gray collet and pulling out

the plug.

7) Remove the red plastic cap from the top of the cartridge.

8) Using tap water, food grade silicone lubricant or glycerin,

wet the O-ring seals to make cartridge insertion easier.

9) Reconnect the red SFC reject tubing by inserting it into the

fitting at the bottom of the new RO membrane cartridge as far

as it will go. Line up the cartridge ears, insert the cartridge

and push it into the head until it is fully seated. Twist the

cartridge 1/4 turn counterclockwise to lock it into place.

10) Open cold water supply valve and carefully check for

leaks. Carefully inspect the fitting at the bottom of the new

RO membrane cartridge.

11) Follow the sanitizing procedure for the storage tank and

the filtration assembly outlined below.

D. YEARLY MAINTENANCE SANITIZATION*

SANITIZING THE RO APPLIANCE

To assure the highest quality water from your RO Drinking

Water Appliance, it is important to routinely sanitize both the

storage tank and the filtration assembly.

IMPORTANT: These procedures are only intended to be

part of a routine maintenance program only and are not

designed to sanitize systems that have become highly

contaminated from misuse.

When to Sanitize the Storage Tank

• Upon start-up as described in the beginning of this manual.

• After any servicing or routine maintenance that involves

replacing the RO membrane cartridge, the postfilter(s), ser-

vicing the storage tank, or replacing the RO faucet.

When to Sanitize the Filtration Assembly

• After any servicing or routine maintenance that involves

replacing the RO membrane cartridge, the postfilter(s), ser-

vicing the storage tank, or replacing the RO faucet.

• After any extended period of non-use (over 30 days) unless

the cartridges are stored inside a sealed plastic bag in the

refrigerator.

Remove the red SFC tubing from

the fitting before completely

removing the RO membrane module

ON

OFF

Fig. 8

14

* Initial sanitization to be performed using instructions on page 6.