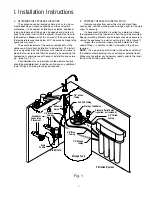

E. MOUNT THE FAUCET

Undercounter installations generally require that the

faucet’s built-in air gap be used. In basement installations,

the built-in air gap does not have to be used if one is provided

elsewhere on the drain line.

For Basement Installations Without An Air Gap Module

See Installation Instructions on page 11.

IMPORTANT NOTE

• The Uniform Plumbing Code dictates that there must be

an air gap between the RO reject line and the waste drain.

An optional non-air gap faucet, which requires a smaller

9/16” mounting hole, is available to make basement in-

stallations easier.

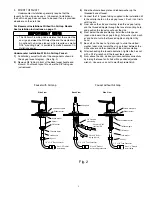

Undercounter Installation With An Air Gap Faucet:

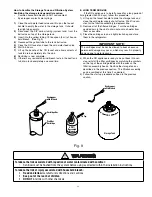

1) Familiarize yourself with all of the components shown in

the air gap faucet diagram. (See Fig. 2)

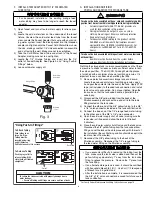

2) Remove 3/8” tubing in front of the black faucet handle and

discard. Push faucet spout into where the 3/8” tubing was

just removed.

3) Slide the chrome base plate and rubber washer up the

threaded base of faucet.

4) Connect the 1/4” green tubing supplied in the installation kit

to the smaller barb on the air gap faucet. Push it on firmly

until it seats.

5) From above the sink counter-top, feed the air gap tubing

and the threaded nipple through the faucet mounting hole

and position the faucet spout over the sink.

6) From below the sink/countertop, install the white spacer

(open side toward the air gap tubing), flat washer, lock wash

er and hex nut onto the threaded nipple and tighten it by

hand.

7) Back off on the hex nut just enough to slide the slotted

washer (open side toward the air gap tubes) between the

white spacer and the underside of the sink/countertop.

8) After rechecking the faucet orientation, tighten the hex nut

with a 9/16” wrench until the faucet feels secure.

9) From above the sink, make any minor orientation corrections

by turning the faucet on its flats with a padded adjustable

wrench. Use care so as not to mar the chrome finish.

5

C.L.

Faucet with Air Gap

Faucet without Air Gap

Side View

Back View

Side View

Chrome base plate

Air Gap hole

1/4” Standard

green tubing

Special red “SFC”

tube from RO

Black 3/8” Reject

tubing to drain

Blue 3/8” Product

water tubing connection

Blue 3/8” Product

water tubing

Rubber washer

Plastic bottom washer

Threaded nipple

Flat washer

Lock washer

Hex nut

Blue 3/8” Product

water tubing

Chrome base plate

Rubber washer

Threaded nipple

Flat washer

Spacer

Hex nut

Slotted washer

Fig. 2

1/4” x 3/8” Tube Connector

1/4” x 3/8” Tube Connector

1/4” x 3/8” Tube Connector

Lock washer