12

7 . Control valve does

not regenerate

automatically but

does when the correct

button(s) is depressed

and held . For

timeclock valves the

buttons are

+

or

–

.

For all other valves the

button is REGEN .

A. Bypass valve in bypass position.

A. Turn bypass handles to place bypass in

service position.

B. Meter is not connected to meter connection on PC

board.

B. Connect meter to three pin connection labeled

METER on PC board.

C. Restricted/stalled meter turbine.

C. Remove meter and check for rotation or

foreign material.

D. Incorrect programming.

D. Check for programming error.

E. Meter wire not installed securely into three

pin connector.

E. Verify meter cable wires are installed securely into

three pin connector labeled METER.

F. Defective meter.

F. Replace meter.

G. Defective PC board.

G. Replace PC board.

8 . Hard or untreated

water is being

delivered .

A. Bypass valve is open or faulty.

A. Fully close bypass valve or replace.

B. Media is exhausted due to high water usage.

B. Check program settings or diagnostics for abnormal

water usage.

C. Meter not registering.

C. Remove meter and check for rotation or

foreign material.

D. Water quality fluctuation.

D. Test water and adjust program

values accordingly.

E. No regenerant or low level of regenerant in

regenerant tank.

E. Add proper regenerant to tank.

F. Control fails to draw in regenerant.

F. Refer to Troubleshooting Guide number 12.

G. Insufficient regenerant level in regenerant tank.

G. Check refill setting in programming. Check refill

flow control for restrictions or debris and, if

necessary, replace.

H. Damaged seal/stack assembly/piston.

H. Replace seal/stack assembly and/or piston.

I. Control valve body type and piston type

mix matched.

I. Verify proper control valve body type and

piston type match.

J. Fouled media bed.

J. Replace media bed.

9 . Control valve uses

too much regenerant .

A. Improper refill setting.

A. Check refill setting.

B. Improper program settings.

B. Check program setting to make sure

they are specific to the water quality and

application needs.

C. Control valve regenerates frequently.

C. Check for leaking fixtures that may be exhausting

capacity or system is undersized.

10 . Residual regenerant

being delivered to

service .

A. Low water pressure.

A. Check incoming water pressure – water pressure

must remain at minimum of 25 psi.

B. Incorrect, damaged, or restricted injector.

B. Replace injector with correct size for

the application.

C. Restricted drain line.

C. Check drain line for restrictions or debris

and remove any obstructions.

11 . Excessive water in

regenerant tank .

A. Improper program settings.

A. Check refill setting.

B. Plugged injector.

B. Remove injector and replace.

C. Drive cap assembly not tightened in properly.

C. Re-tighten the drive cap assembly.

D. Damaged seal/stack assembly/piston.

D. Replace seal/stack assembly and/or piston.

E. Restricted or kinked drain line.

E. Check drain line for restrictions or debris and or

unkink drain line.

F. Plugged backwash flow controller.

F. Remove backwash flow controller and replace, if

necessary.

G. Missing refill flow controller.

G. Install refill flow controller.

PROBLEM CAUSE

CORRECTION

TROUBLESHOOTING GUIDE

Summary of Contents for ASP-TW

Page 16: ...16 This page intentionally left blank...

Page 17: ...17 This page intentionally left blank...

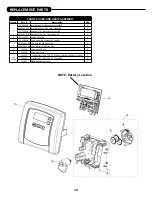

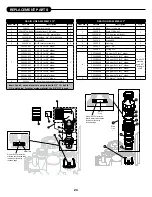

Page 20: ...20 REPLACEMENT PARTS...