4

“TREATED”

WATER EXITS

SUPPLY

WATER ENTERS

NORMAL OPERATION

POSITION

BYPASS POSITION

DIAGNOSTIC POSITION

SHUT OFF POSITION

FIGURE 1

SUPPLY

WATER EXITS

SUPPLY

WATER ENTERS

FIGURE 3

SUPPLY

WATER EXITS

SUPPLY

WATER ENTERS

FIGURE 2

NO

WATER EXITS

SUPPLY WATER IS

SHUT OFF

TO THE HOUSE

AND THE VALVE

FIGURE 4

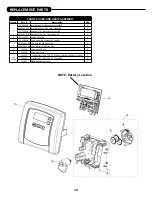

BYPASS VALVE

The bypass valve is typically used to isolate the control valve from the plumbing system’s water pressure in order to perform control

valve repairs or maintenance. The 1” full flow bypass valve incorporates four positions, including a diagnostic position that allows a

service technician to have pressure to test a system while providing untreated bypass water to the building. Be sure to install bypass

valve onto main control valve before beginning plumbing or make provisions in the plumbing system for a bypass. The bypass body and

rotors are glass-filled Noryl® and the nuts and caps are glass-filled polypropylene. All seals are self-lubricating EPDM to help prevent

valve seizing after long periods of non-use. Internal “O” Rings can easily be replaced if service is required.

The bypass consists of two interchangeable plug valves that are operated independently by red arrow shaped handles. The handles

identify the direction of flow. The plug valves enable the bypass valve to operate in four positions.

1.

NORMAL OPERATION POSITION:

The inlet and outlet handles point in the direction of flow indicated by the engraved

arrows on the control valve. Water flows through the control valve for normal operation of a water softener or filter. During the

regeneration cycle this position provides regeneration water to the unit, while also providing untreated water to the distribution

system

(Fig. 1)

.

2.

BYPASS POSITION:

The inlet and outlet handles point to the center of the bypass. The system is isolated from the water

pressure in the plumbing system. Untreated water is supplied to the building

(Fig. 2)

.

3.

DIAGNOSTIC POSITION:

The inlet handle points toward the control valve and the outlet handle points to the center of bypass

valve. Untreated supply water is allowed to flow to the system and to the building, while not allowing water to exit from the system

to the building

(Fig. 3)

. This allows the service technician to test the unit and perform other functions without disrupting the water

going to the building.

NOTE

:

The system must be rinsed before returning the bypass valve to the normal position.

4.

SHUT OFF POSITION:

The inlet handle points to the center of the bypass valve and the outlet handle points away from the

control valve. The water is shut off to the building. The water treatment system will depressurize upon opening a tap in the building.

A negative pressure in the building combined with the unit being in regeneration could cause a siphoning to the building. If water

is available on the outlet side of the unit, it is an indication of water bypassing the system

(Fig. 4)

(i.e. a plumbing cross-connection

somewhere in the building).

Summary of Contents for ASP-TW

Page 16: ...16 This page intentionally left blank...

Page 17: ...17 This page intentionally left blank...

Page 20: ...20 REPLACEMENT PARTS...