14

7. Control valve does not

regenerate automatically

but

does

when the

correct button(s) is

depressed and held.

For timeclock valves the

buttons are

▲

&

▼

.

For all other valves the

button is REGEN.

A . Bypass valve in bypass position

A . Turn bypass handles to place bypass in

service position

B . Meter is not connected to meter connection on

PC board

B . Connect meter to three pin connection labeled

METER on PC board

C . Restricted/stalled meter turbine

C . Remove meter and check for rotation or

foreign material

D . Incorrect programming

D . Check for programming error

E . Meter wire not installed securely into three

pin connector

E . Verify meter cable wires are installed securely

into three pin connector labeled METER

F . Defective meter

F . Replace meter

G . Defective PC board

G . Replace PC board

8. Hard or untreated

water is being

delivered

A . Bypass valve is open or faulty

A . Fully close bypass valve or replace

B . Media is exhausted due to high water usage

B . Check program settings or diagnostics for

abnormal water usage

C . Meter not registering

C . Remove meter and check for rotation or

foreign material

D . Water quality fluctuation

D . Test water and adjust program

values accordingly

E . No regenerant or low level of regenerant in

regenerant tank

E . Add proper regenerant to tank

F . Control fails to draw in regenerant

F . Refer to Troubleshooting Guide number 12

G . Insufficient regenerant level in regenerant tank

G . Check refill setting in programming . Check

refill flow control for restrictions or debris and

clean or replace

H . Damaged seal/stack assembly

H . Replace seal/stack assembly

I . Control valve body type and piston type

mix matched

I . Verify proper control valve body type and

piston type match

J . Fouled media bed

J . Replace media bed

9. Control valve uses too

much regenerant

A . Improper refill setting

A . Check refill setting

B . Improper program settings

B . Check program setting to make sure

they are specific to the water quality and

application needs

C . Control valve regenerates frequently

C . Check for leaking fixtures that may be

exhausting capacity or system is undersized

10. Residual regenerant

being delivered to

service

A . Low water pressure

A . Check incoming water pressure – water

pressure must remain at minimum of 25 psi

B . Incorrect, damaged, or restricted injector

B . Replace injector with correct size for

the application

C . Restricted drain line

C . Check drain line for restrictions or debris

and clean

11. Excessive water in

regenerant tank

A . Improper program settings

A . Check refill setting

B . Plugged injector

B . Remove injector and clean or replace

C . Drive cap assembly not tightened in properly

C . Retighten the drive cap assembly

D . Damaged seal/stack assembly

D . Replace seal/stack

E . Restricted or kinked drain line

E . Check drain line for restrictions or debris and

or unkink drain line

F . Plugged backwash flow controller

F . Remove backwash flow controller and clean

or replace

G . Missing refill flow controller

G . Replace refill flow controller

PROBLEM

CAUSE

CORRECTION

TROUBLESHOOTING GUIDE

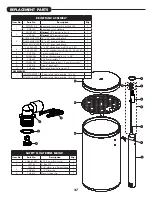

Summary of Contents for Impression Plus IMP-1044TW

Page 22: ...22 REPLACEMENT PARTS...