-2-

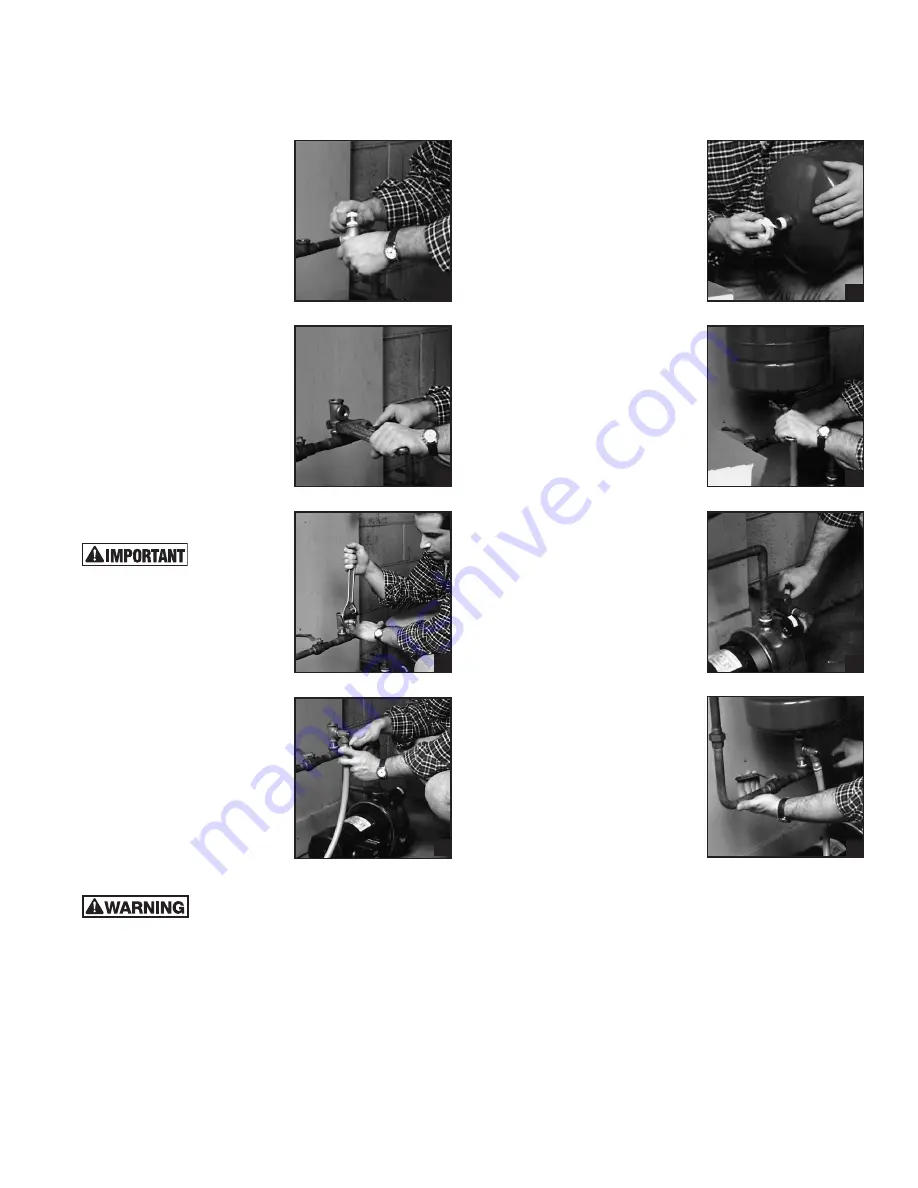

6. Put together pipe tee assembly.

a. Wrap Teflon

®

tape around the

male threads on both ends of the

close nipple. Apply clockwise (i.e.

bottom up and coming towards

you). Or apply pipe sealant.

b. Install the close nipple into the

pipe tee. Tighten hand tight.

(Fig. 4)

c. Install the other end of the close

nipple by inserting it into the

female threaded opening in the

supply line from the pump, where

the old tank was installed. (The

close nipple now has the pipe tee

pointing straight up.) Tighten the

tee using a pipe wrench 3-4 turns

after hand tight.

Point the opening on the side

of the tee to the front or to the

side so that it is easily accessible.

(Fig. 5)

7. Check to see whether you have

a pressure relief valve installed

somewhere between the pump

and the tank. If you do, then skip

this step.

Always

be

sure to equip

your well system with a proper

pressure relief valve.

If you do not yet have one in

the system between your pump

and tank: Install the pressure

relief valve in the straight pipe

tee. Wrap Teflon

®

tape around

the male threads. Or apply pipe

sealant. Insert the male end

into the other female threaded

opening on the pipe tee. Tighten

hand tight. Tighten wrench tight

using the adjustable wrench.

(Fig. 6)

8. Attach a pipe or hose to steer any

emergency overflow water away

from the electrical connections

of the pump if necessary.

Do not

install a plug or valve or insert

anything else in the pressure

relief valve that would obstruct

the flow of water from it. This

can create a serious safety

hazard in your home.

A drip pan connected to an adequate drain

must be installed if leaking and flooding

could cause property damage to the area adjacent to the

appliance or to lower floors of the structure.

If the pressure relief valve is located above something that

could be damaged by spilled water, then attach a pipe or hose

to the valve to redirect any emergency discharge.

(Fig. 7)

Cut a 1/2” plastic hose to a length long enough to steer water

clear of whatever you don’t want to get wet. Insert one end

of the plastic hose over the end of the 1/2” plastic hose barb.

Screw the barb hose assembly

into the pressure relief valve.

Tighten wrench tight with the

adjustable wrench.

9. Install the new tank.

a. Wrap Teflon

®

tape around the

threads of the male connection

on the tank or apply pipe sealant.

(Fig. 8)

b. Install the new tank in the

female threaded opening of

the pipe tee. Turn hand tight.

Tighten wrench tight using the

12” adjustable wrench on the

hex connection at the bottom of

the tank.

(Fig. 9)

c. Remove the plastic cap on the

air valve on top of the tank.

Check the air charge in the tank

using the tire pressure gauge.

Adjust the pre-charge pressure

in the tank to be 1 to 2 psi

below the pressure switch pump

cut-in setting. First, look inside

the cap to the pressure switch

to determine the pump cut-in

setting. It should say “20/40” or

“30/50” or the like. The pressure

in the tank should be adjusted

to be 2 psi below the lower of

these two numbers. That is, the

tank pressure should be set at

about 18 psi if the cap indicates

a setting of 20/40, or set at

about 28 if the cap indicates a

setting of 30/50.

Models HT2B, HT4B and HT8B

are pre-charged with 38 psi

when shipped from the factory.

If this charge is too high, release

some air by pressing down on

the pin inside the air valve. If the

charge is too low, pump it up

using a bicycle tire pump.

Alternatively, you can adjust

the pressure switch to match

the pressure in the tank. See

instructions on the inside of the

cap to the pressure switch for

how to do this.

10. Open the ball or gate valve on the

pump feed line (that you closed

in Step 4).

(Fig. 10)

This will allow the pump to draw water

from the well into the house.

Open the ball or gate valve on the supply line (that you

closed in Step 2).

(Fig. 11)

This will allow the well system to

pump water into the plumbing in your house.

Shut off the faucet upstairs!

11. Turn on the power.

12. Look for leaks. If there are any, shut the power off. Tighten

or redo the leaky connections.

4

8

9

10

11

5

6

7