WATERAX

STRIKER-2/3 Owner's Manual

09/2015

21

Assembly Procedure for Pump End

(Similar procedure for the 25-16S, will have fewer impeller and distributor)

13

14

15

16

17

18

19

20

25

21

22

23

24

26

19

(2/2)

Important:

When reusing components, carefully inspect the parts. Ensure that key dimensions are within

acceptable limits. Visually inspect the parts for pitting, worn vanes, damaged threads, damaged gasket

faces, excessive corrosion, deformation, etc. Discard any component that is not within acceptable

standards. Ensure that the components are clean before installing.

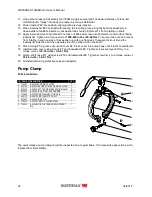

Mechanical Rotary Seal:

The mechanical rotary seal requires careful

inspection. The seal should be discarded if there are signs of leaks or if the

internal drive bushing is excessively deformed. The drive bushing must be

free to rotate without contact with the brass housing. If there is contact

between the drive bushing and the housing, the seal must be discarded.

1. Slide bearing retaining ring #16 on shaft #14 with plain face toward coupling collar.

2. Press bearing #17 on shaft using tool 600052.

3.

Carefully

press rotary seal #18 in pump body #3 using pressing sleeve tool 700531.

4. Apply a small amount of dish soap on mechanical rotary seal O-ring to facilitate installation of pump

shaft. Carefully pass end of shaft assembly through mechanical rotary seal bore. Make sure that flat

sections of shaft line up with rotary seal drive bushing flat sections. Gently press down shaft until ball

bearing rests firmly against shoulder in pump body. To verify that shaft has been properly installed,

slowly rotate shaft by hand; rotary seal drive bushing should rotate with shaft.

5. Attach retaining ring #16 to pump body with six screws #15 to a torque value of

22-25 in-lbs / 2.5-2.8

Nm

. Tighten evenly.

6. A small amount of marine grease can be applied onto shaft to facilitate future disassembly.

7. Slide impeller #19 onto shaft, and engage with mechanical rotary seal.

8. Smear the O-rings with a suitable lubricant to facilitate assembly.

9. Place O-ring #25 in groove of distributor #20.

10. With open end of pump body in vertical position, carefully lower distributor #20 until it rests on bottom

of body. Ensure that O-ring did not fall out of position during installation of distributor.

11. Slide impeller #19 into position, aligning with previous impeller.

12. Place O-ring #26 in groove of distributor #21.

ID ITEM NO DESCRIPTION

QTY

25-16S

QTY

18-16S

13 700006

12-17 COUPLING BUFFER

1

1

14 700042

18-2C PUMP SHAFT FOR 18-16

-

1

14 700066

25-2C PUMP SHAFT FOR 25-16

1

-

15 800364

12-25 SCREW #8-32X7/16 PHILLIPS

FLAT NYLON LOCK SS

6

6

16 700032

12-3 RETAINING RING FOR BEARING,

ALU.

1

1

17 700044

12-48S DOUBLE ROW BALL BEARING

WITH SEAL

1

1

18 700008

12-28NS MECHANICAL ROTARY SEAL

1

1

19 700036

12-7 IMPELLER, ALU.

1

2

20 700014

12-6 DISTRIBUTOR, ALU.

1

1

21 700065

12-9 DISTRIBUTOR, ALU.

-

1

22 700074

12-11 IMPELLER, ALU

1

1

23 600089

12-49 LOCKWASHER SS

1

1

24 700012

12-50 LOCK NUT SS

1

1

25 800450

12-26 O-RING

1

1

26 800363

12-27 O-RING

-

1

- 701169

GASKET BURASIL FOR 12-28NS SEAL

-

-

- 701170

O-RING FOR 12-28NS SEAL

-

-

NOTE:

The sealed bearing eliminates pump failure dangers related to improper

greasing by completely removing the need to grease the pump end bearing.

Drive bushing

shoulders in

contact with

seal housing;

seal must be

discarded.