INSTALLATION

Receive and Check Pump

Check the pump packaging for damage. Check for shipping damage such as dented, cracked

or bent parts. If damage is detected contact the shipper or distributor from which the pump

was purchased.

Lifting and Handling

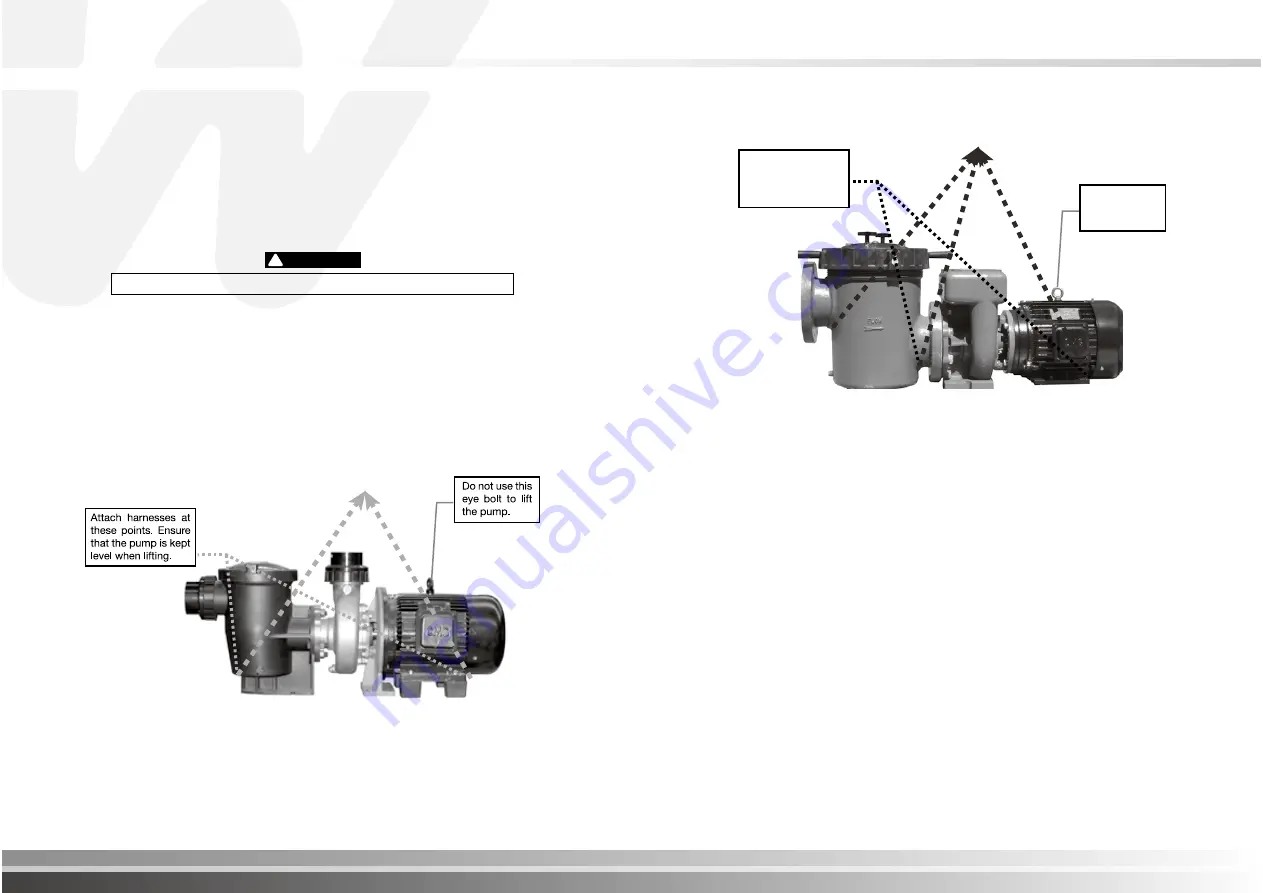

a) Hydrostar Pump Procedure

This pump requires two people to move and position the pump into place.

b) Hydrosteel Pump Procedure

The eye bolt built into the motor body is not designed to support the combined weight of the

motor and pump body. DO NOT attempt to lift the pump by attaching a clip to this eye bolt.

Use a minimum of two chains or straps to support the entire motor and pump. The crane or

hoist used, as well as each individual chain or strap, must have a weight-bearing capacity in

excess of the combined weight of the motor and pump.

c) Cast Iron Pump Procedure

The eye bolt built into the motor body is not designed to support the combined weight of the

motor and pump body. DO NOT attempt to lift the pump by attaching a clip to the eye bolt.

Use a minimum of two (preferably three) chains or straps to support the entire motor and

pump. The crane or hoist used, as well as each individual chain or strap, must have a weight-

bearing capacity in excess of the combined weight of the motor and pump.

I pg 05

WARNING

!

Crushing Hazard. NEVER walk or reach under a suspended pump.

For models where the wet end is made out of a composite material instead of cast iron – DO

NOT place any straps under the wet end for lifting – this will cause the wet end to crack. In

these scenarios – place the lifting strap under the pump housing.

Lifting Procedure

i) Raise the pump slowly to ensure that the chains or straps will not slip when

under tension.

ii) Check that the pump is properly balanced when it is raised. If it is not, release the

tension on the chains or straps and readjust their position.

Pump Location

a) The pump should be located in a position that enables easy access for periodic servicing.

Leave the area above the pump lid clear for removal of the basket for cleaning.

b) The pump and other circulation equipment must be located a minimum of 1.5m (5ft) from

the water.

c) The pump elevation should not be more than a few feet above the water level of the pool;

it is recommended that the pump be located within 0.30m (1ft) of the water level.

d) If the pump is installed below water level, shut off valves (butterfly valve for 80mm or

larger) should be installed on both the suction and discharge piping to prevent back flow

of pool water during routine servicing of the pump and other circulation equipment.

e) Place the pump on a solid foundation that will not vibrate. It is suggested that the pump

be bolted down to reduce noise from vibration.

f)

The pump foundation must have adequate drainage to prevent the motor from being flooded.

g) Protect the pump from the sun and rain.

h) Install the pump in a well-ventilated area – ensure there is enough clearance around the

motor and fan cowl.

If the pump is installed under cover, provide adequate ventilation and lighting.

Attach harnesses at

these points. Ensure

that the pump is kept

level when lifting.

Do not use this

eye bolt to lift

the pump.

Waterco Commercial Pump