Section 4 – Peristaltic Dosing Pumps

22

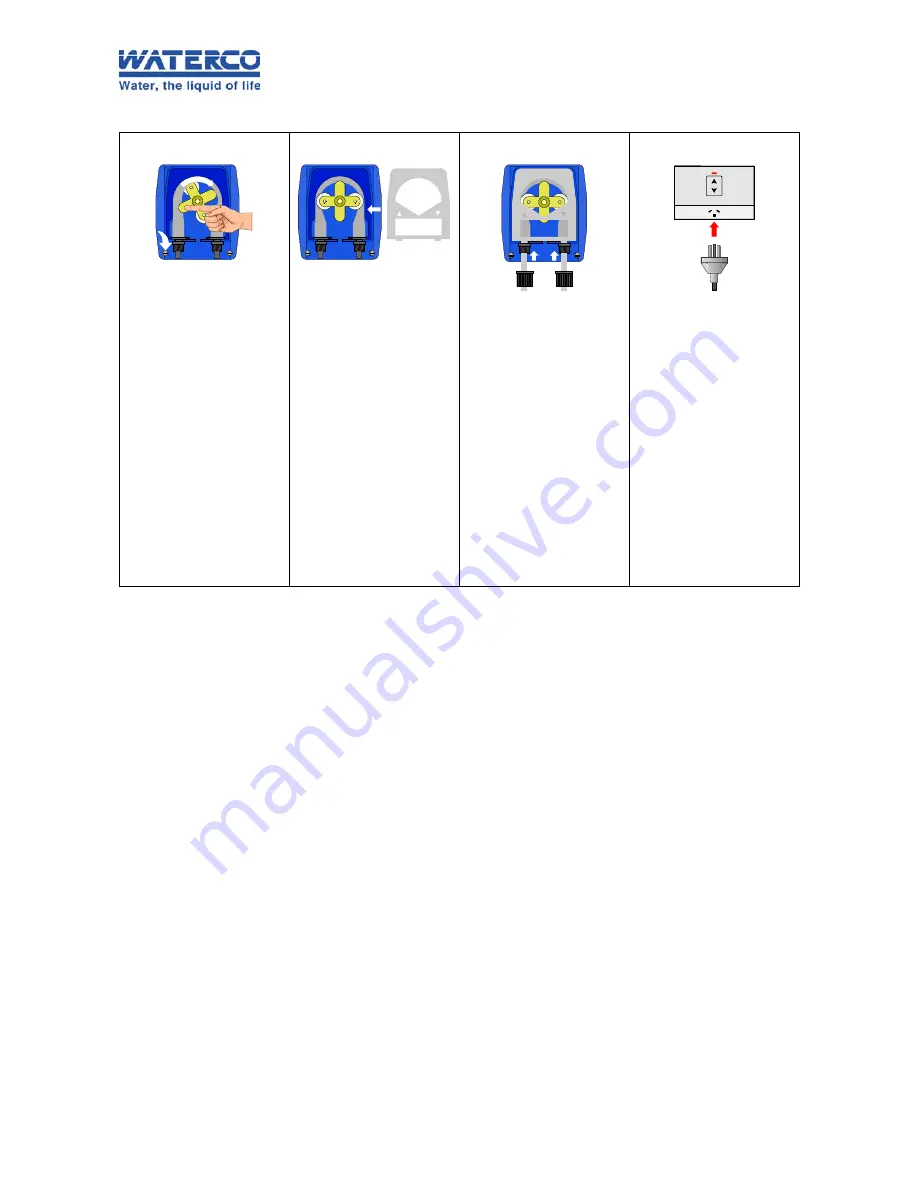

To fit a new Pump Tube…

2

3

4

1

Turn the roller holder so

that the rollers are in a

horizontal line. Push the

left hand side

compression fitting into

its seat, round side

facing in. Begin turning

the roller holder

clockwise, so that the

roller holder acts as a

lever which pulls the

pump tube in as it turns.

After approximately 3/4

of a turn, the right hand

side compression fitting

can be pushed in, round

facing in.

The new pump tube has

now been fitted.

Replace the see-through

cover on the front of the

pump. This is essential

to protect the rollers and

tube from dirt and

moisture.

Re-fit the Input and

Output tubing to the

compression fittings.

See the procedure

detailed in section 2.4.

The power to the

Chemflo

can now be

re-connected and

switched on.

4.3 Dosing Pump Error Message

The

Chemflo

monitors the dosing pump current usage and will detect problems with the pump

before damage can occur. If excess current is detected the unit will beep and display

Pump

in the

status window for pH or ORP. No further dosing of the chemical will occur and steps should be

taken to eliminate the fault.

Turn the unit OFF and check the pump tubing for kinks and ensure that the output tube is not

obstructed. A worn / faulty gearbox and motor can cause high current usage and will require

replacement.

The error message will be reset by turning the unit off or by pressing the Menu key. The fault will

re-occur the next time dosing is required if the cause has not been eliminated.