I

pg 11

Heat Pump Swimming Pool Heaters

Bonding

Because all metals have different electrical potentials, ALL metal and electrical components of the pool system

MUST be bonded together. This includes the metal framework of the pool, the light, the pump, the filter (if metal),

the heater, any automatic chlorine generator, and any other metal or electrical equipment.

On some older pools, this substructure bond wire may not exist. In these cases, a 0.9 - 1.2m solid copper rod

must be driven into the ground near the equipment, all electric equipment and metal components must be

bonded to each other and to the copper rod. Warranty will be void if system is not properly bonded.

GETTING TO KNOW YOUR POOL HEATER

Operation of Square Electronic Control

!

VITAL

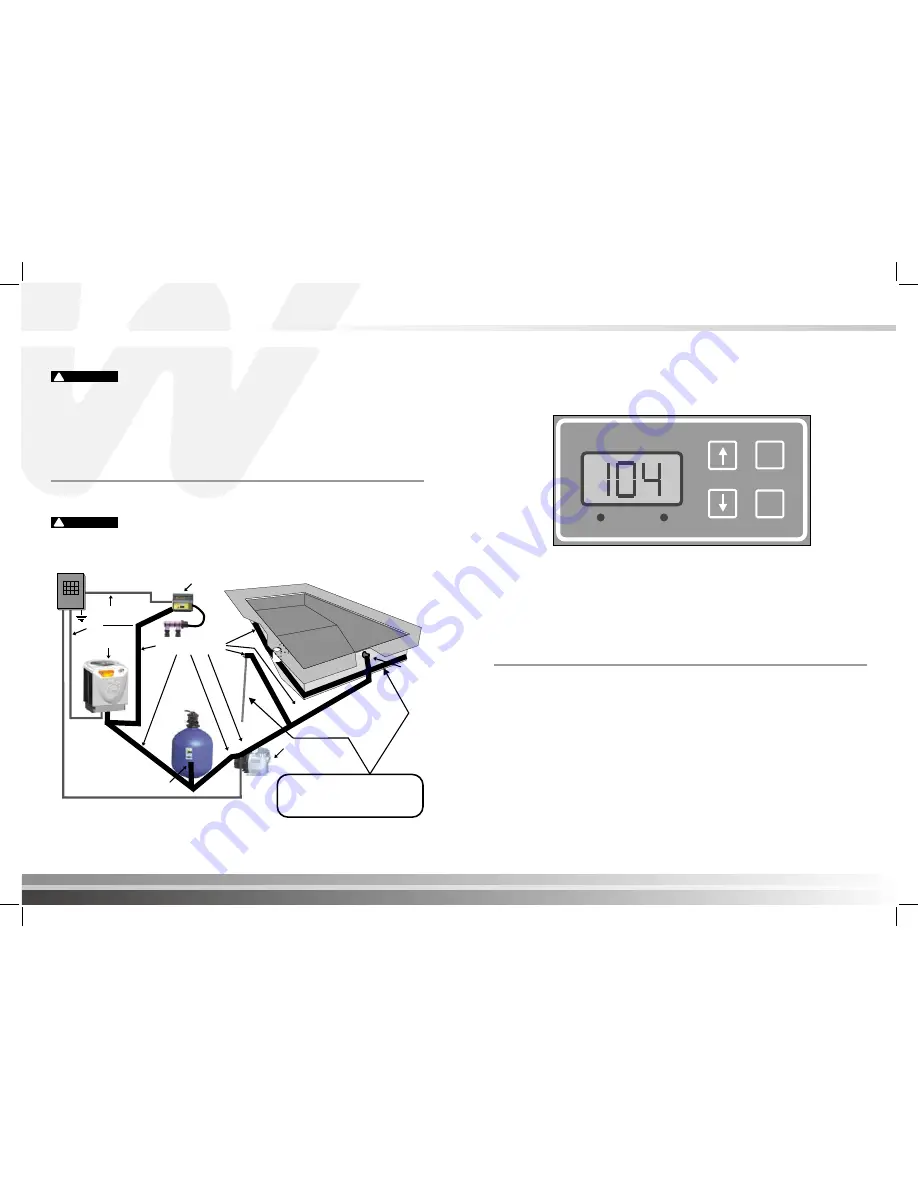

Bonding Diagram

!

VITAL

Digital Control Panel

The digital display, electronic temperature control always displays the water temperature setting. To power on the

temperature control, press the ON/OFF button.

To modify the desired water temperature, simultaneously press on the TEMP SET control arrows on the keypad

for approximately 3 seconds, or until the temperature display flashes. The arrows will raise (up arrow) or lower

(down arrow) the temperature setting. Once the display no longer flashes, the desired temperature is now set. To

change the temperature display mode, press on the ˚C/ ˚F button.

˚C

˚F

ON/OFF

˚C/ ˚F

Pool House

Breaker Box

Power Supply

and Grounding

Wires Conduits

Chlorine

Generator

Heat Pump

If Metal Filter

Pool Pump

If Pool Bonding Wire does

not exist, then a 0.9 - 1.2m Copper Rod

must be driven into the ground and

equipment bonded to it.

Light

0.

9

- 1

.2

m

C

op

pe

r R

od

Bonding Wires

Pool

Bond

ing W

ire