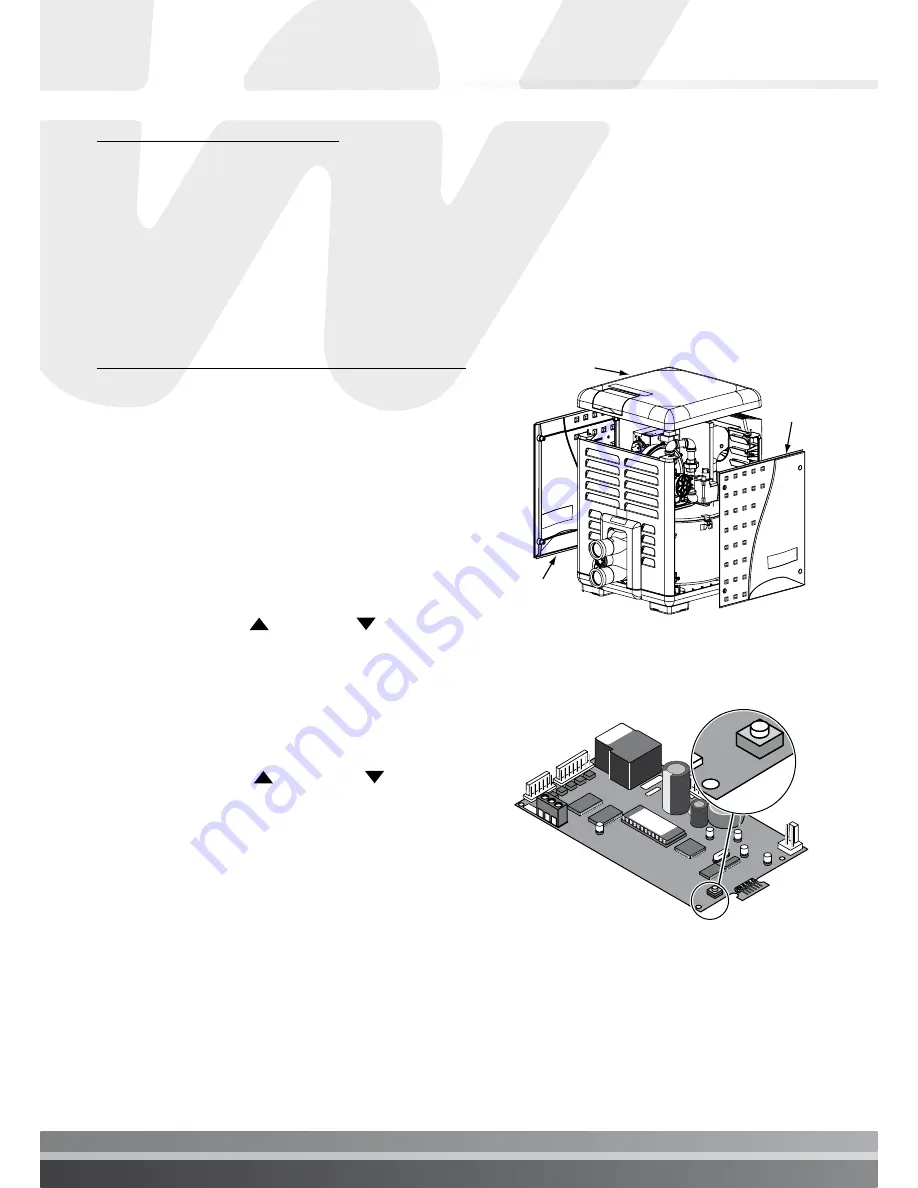

Figure 33.

MAXIMUM TEMPERATURE SET POINT

1. Unbolt and remove the door panels (see Figure

33).

2. Access the control panel board on the underside

of the top cover. Locate the yellow button on the

corner of the control board.

3. Push the

Max. Temp. Set Point

button on the

back of the control board (see Figure 34).

The following sequence should happen:

A. The unit turns on and the

POOL ON

light will

turn on.

B. Press the

TEMP

or

TEMP

pad (on

TOP of the panel) to set maximum pool

temperature.

C. Wait up to 30 seconds; the

POOL ON

light

will turn off and the

SPA ON

light will turn on.

To override the time delay, push the

Max.

Temp. Set Point

button again.

D. Press the

TEMP

or

TEMP

button

on the control panel and set maximum spa

temperature to 40°C (104° F) or less.

E. Wait up to 30 seconds; the

SPA ON

light

will turn off and the unit will shut down.

To override the time delay, push the

Max.

Temp. Set Point

button again.

4. Reinstall the access door panels.

TEMPERATURE SETTING

The heater comes factory set at 25.6° C (78° F). for the pool mode and 37.8° C (100° F). for the

spa mode. Using the up and down arrows, you can set the pool/spa thermostats to a minimum

temperature of 18.3° C (65° F.), or a maximum of 40° C (104° F). If you desire to heat only one

body of water, the thermostat is capable of an off mode. As an example, if you only wish to heat

the spa and not the pool, simply depress and hold the pool down arrow, and the thermostat will

lower its setting to 18.3° C (65° F.) then go to an off mode.

See below to change the heater’s

factory set temperature settings.

Door

Access

Panel

Top Panel

Door

Access Panel

S1

SET

MAX

S1

SET

MAX

Figure 34.