8

Emerald Gas Insert Zero Clearance Kit

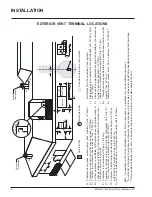

INSTALLATION

Secure to the Lower Back Section with 4 screws (from the

inside).

From the outside, secure with 2 screws on each side.

2)

Set the assembled Side and Base sections upright. Slide

the Lower Back (the section with 4 holes) down the inside

of Side flanges (make sure the 4 holes are closest to the

floor - see photo).

Secure with 2 screws on each side, and 11 screws on the

back.

Right

Side

screw

Attach with 2 screws on the side. Repeat for Left Side

Attach with 11 screws on the side.

3)

Slide the Upper Back Section down the inside of the Side

flanges.

Summary of Contents for E61

Page 16: ...Printed in Canada...