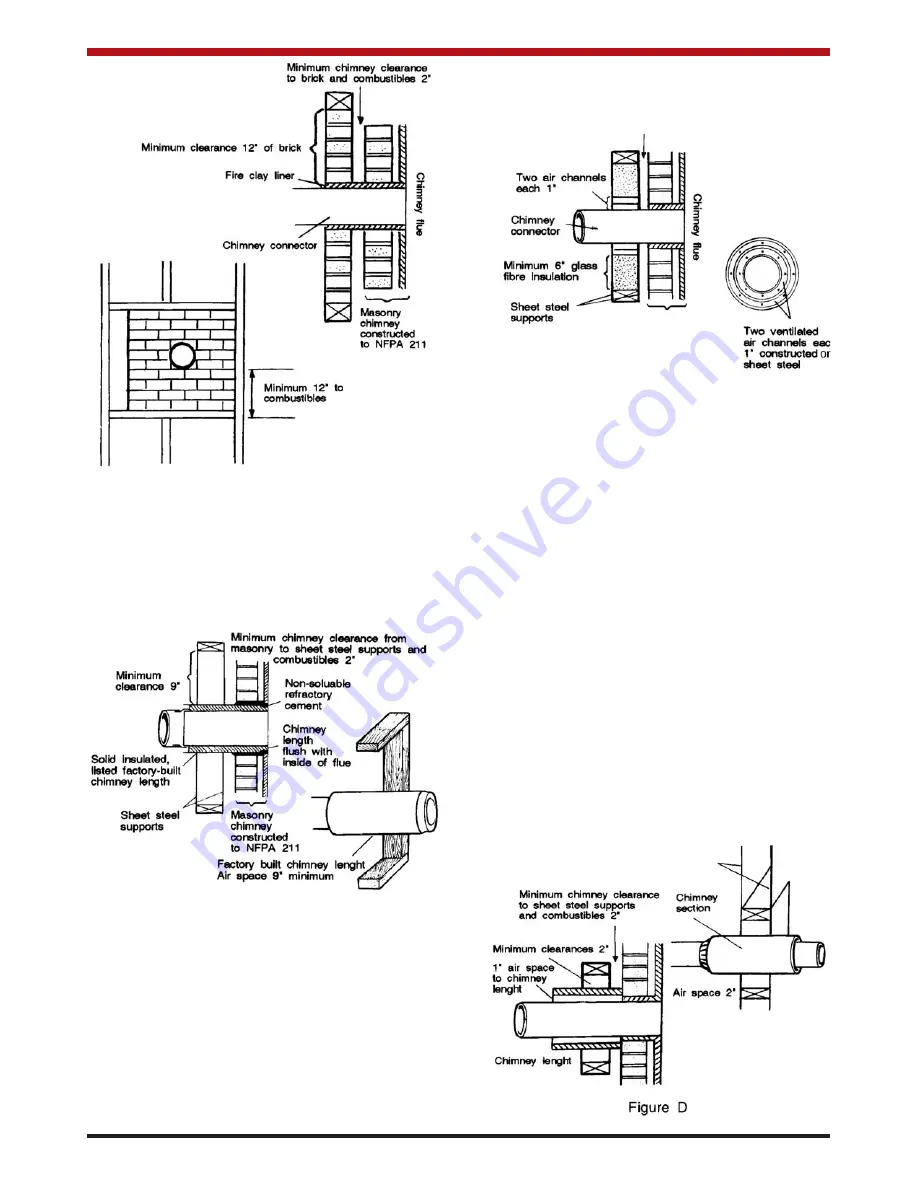

penetration with nonwater-soluble refractory

cement. Supports should be securely fas

tened to wall surfaces on all sides. Fasteners

between supports and the chimney length

shall not penetrate the chimney liner.

3.

Sheet metal chimney connector, min. 24

gauge in thickness, with a ventilated thimble,

min. 24 gauge in thickness, having two 1” air

channels, separated from combustibles by a

min. of 6” of glass fibre insulation. Opening

should be covered and thimble supported

with a sheet steel support, min. 24 gauge in

thickness. Support should be securely fas

tened to wall surfaces on all sides and

should be sized to fit and hold chimney

section. Fasteners used to secure chimney

sections should not penetrate chimney flue

liner.

4.

Solid insulated listed factory-built chimney

length with an inside diameter 2” larger than

the chimney connector and having 1” or

more of insulation, serving as a pass-

through for a single wall sheet steel chimney

connector of min. 24 gauge thickness, with a

min. 2” air space between the outer wall of

chimney section and combustibles. Min.

length of chimney section shall be 12”.

Chimney section concentric with and spaced

1” away from connector by means of sheet

steel support plates on both ends of chimney

section. Opening shall be covered and

chimney section supported on both sides

with sheet steel supports of min. 24 gauge

thickness.

Supports should be securely fastened to wall sur-

face on all sides and shall be sized to fit and hold

chimney section. Fasteners used to secure chimney

sections should not penetrate chimney flue liner.

8

FIGURE B

FIGURE A

FIGURE C