MAINTENANCE

CREOSOTE -

Formation and the need for removal.

When wood is burned slowly, it produces tar and

other organic vapours, which combine with expelled

moisture to form creosote. The creosote vapours

condense in the relatively cool chimney flue of a

slow burning fire. As a result creosote residue accu-

mulates on the flue lining. When ignited this cre-

osote makes an extremely hot fire. The chimney

connector and chimney should be inspected at least

twice monthly during the heating season to deter-

mine if a creosote build-up has occurred. If creosote

has accumulated it should be removed to reduce the

risk of chimney fire.

Inspect the chimney connector frequently. Tap the

connector with your finger when the pipe is cool. If

you hear a dull echo, the pipe may need cleaning.

Disassemble the chimney connector and clean the

sections. Replace corroded pipe sections. The fit-

ting of a slip-joint in the stove makes the dismantling

easy for cleaning and inspection of chimney and

stove.

When inspecting a masonry chimney, start at the

cleanout door, normally found in the basement, at

the base of the chimney, or on the outside. If your

chimney does not have a clean-out door it must be

inspected and cleaned by removing stove from

chimney.

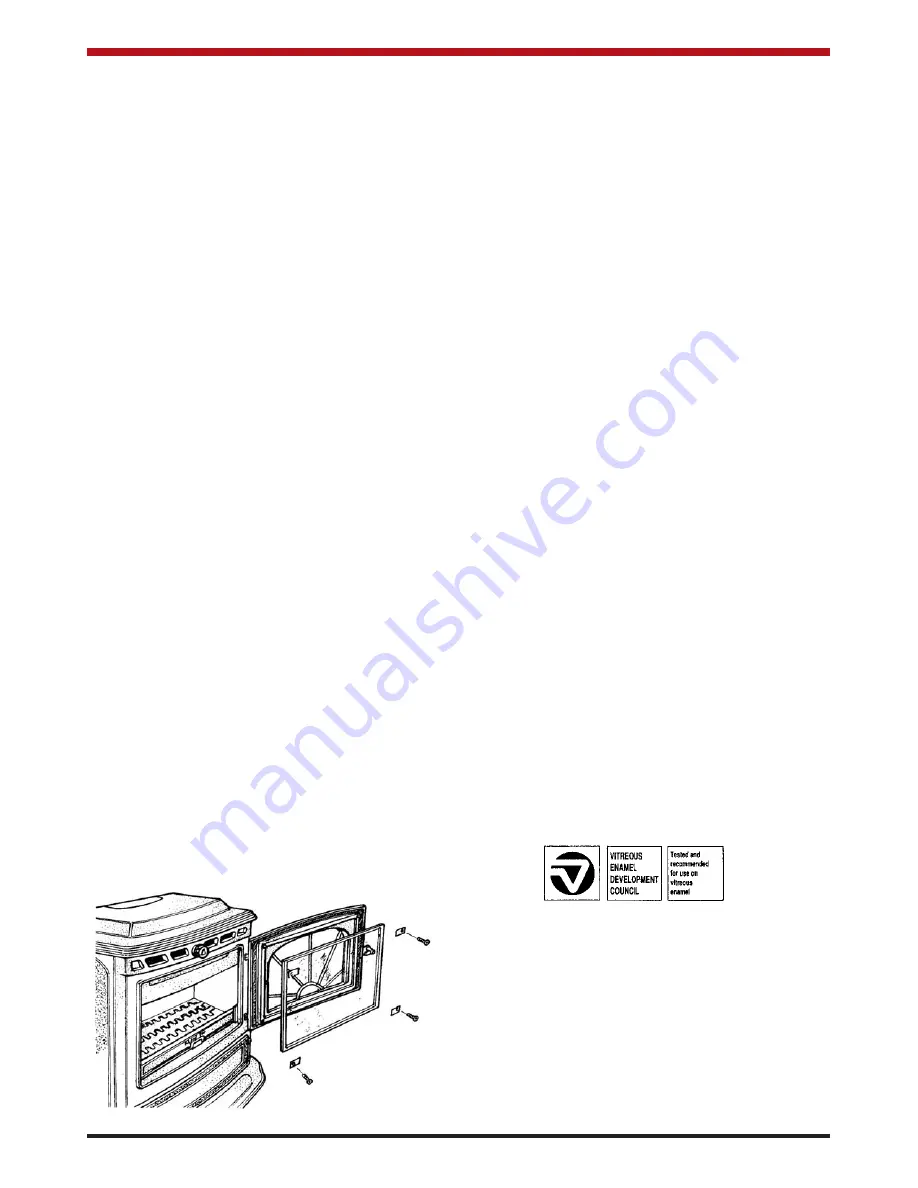

GLASS REPLACEMENT

(a)

Open the firedoor (item 8) fully.

(b)

Remove the four corner screws and clips

(items 38 & 39) and carefully remove the

broken glass.

(c)

Clean the glass recess in the door.

(d)

Attach adhesive thermal tape to the

perimeter of the replacement glass.

11

(e)

Place the thermal taped side of the glass into

the firedoor recess and replace the four

corner clips (items 38 & 39) and screws.

(f)

Make sure that the large corner clip (item 39)

is fitted in the top right hand corner.

(g)

Tighten screws.

(h)

Replace glass only with ceramic glass 3/16”

(5mm) thick.

GLASS CLEANING

The glass will clean itself when there is sufficient

heat generated by the burning fuel. If a build-up of

creosote occurs on the glass due to poor draught

conditions, poor quality fuel or very low burning for

long periods of time, it is best to clean the glass

manually when glass is thoroughly cooled.

VITREOUS ENAMEL CLEANING

General cleaning must be carried out when the

stove is cool.

If this stove is finished in a high gloss vitreous

enamel, to keep the enamel in the best condition

observe the following tips:

1.

Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry duster.

2.

For stubborn deposits a soap impregnated

pad can be carefully used on the vitreous

enamel.

3.

Use only products recommended by the

Vitreous Enamel Department Council, these

products carry the Vitramel label.

4.

DO NOT USE ABRASIVE PADS OR OVEN

CLEANSERS CONTAINING CITRIC ACID

ON ENAMELLED SURFACES. ENSURE

THAT THE CLEANSER MANUFACTUR

ERS INSTRUCTIONS ARE ADHERED TO.