12

NSZ/NDZ INSTALLATION MANUAL

NOTE:

For closed loop systems with antifreeze protection, set

SW2-2 to the “loop” position (see DIP Switch Settings table).

Once piping is completed between the unit, pumps and the

ground loop (see figure below), final purging and charging

of the loop is required. A flush cart (or a 1.5 HP pump

minimum) is needed to achieve adequate flow velocity

in the loop to purge air and dirt particles from the loop

itself. Antifreeze solution is used in most areas to prevent

freezing. Flush the system adequately to remove as much

air as possible then pressurize the loop to a static pressure

of 40-50 PSI (summer) or 50-75 PSI (winter). This is

normally adequate for good system operation. Loop static

pressure will fluctuate with the seasons. Pressures will be

higher in the winter months

than during the cooling season.

This fluctuation is normal and

should be considered when

initially charging the system.

After pressurization, be sure

to remove the plug in the end

of the loop pump motor(s) (if

applicable) to allow trapped air

to be discharged and to ensure

that the motor housing has been

flooded. Ensure that the loop

pumps provide adequate flow

through the unit(s) by checking

the pressure drop across the

heat exchanger and comparing

it to the unit capacity data

in the specification catalog.

Usually 2.5 to 3 GPM of flow

per ton of cooling capacity is

recommended in earth loop

applications.

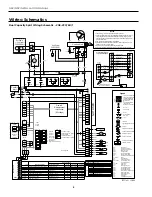

Figure 7: Typical Split System Application Closed Loop - Earth Coupled

Disconnect

Thermostat Wire

From Air Handler

Vibration Absorbing Pad or Air Pad

P/T Plugs

Lineset

To Air

Handler

Insulated

Flow Center

Electrical Supply

GeoLink

Flow Center

To Loop

DHW Out

Rubber Hose Connector

Kit CK4L or CK4S

DHW In

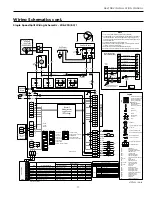

Envision to

Electromechanical Units

Shut

Down

C C

SL1

In

SL1

Out

Envision Unit #1

To Electromechanical Unit

C

S

Shut

Down

C C

Shut

Down

C C

SL1

In

SL1

Out

SL1

In

SL1

Out

Single Speed

Envision Unit #1

With pump

wired to Unit 1

With pump

wired to

Unit 2

Envision to Envision

Microprocessor Units

Envision Unit #2

Single Speed

With pump

wired to Unit 1

With pump

wired to

Unit 2

Shut

Down

C C

Shut

Down

C C

SL1

In

SL1

Out

SL1

In

SL1

Out

Dual Capacity

Envision Unit #1

Envision Unit #2

Dual Capacity

Envision to Envision

Microprocessor Units

Figure 8: Primary/Secondary Hook-up

Closed Loop - Ground Source Systems

Multiple Units on One Flow Center

When two units are connected to one loop pumping

system, pump control is automatically achieved by

connecting the SL terminals on connector P2 in both units

with 2-wire thermostat wire. These terminals are polarity

dependant (see Figure 8). The loop pump(s) may be

powered from either unit, whichever is more convenient. If

either unit calls, the loop pump(s) will automatically start.

The use of two units on one flow center is generally limited

to a total of 20 GPM capacity.