19

NSZ/NDZ INSTALLATION MANUAL

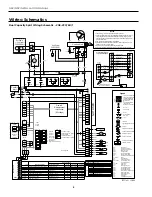

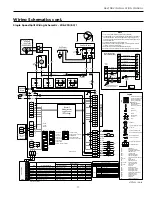

Microprocessor Control cont.

Heat, 3rd Stage (Y1,Y2,W) Single-Speed Units

The first stage of resistance heat is energized 10 seconds

after “W” input, and with continuous 3rd stage demand,

the additional stages of resistance heat engage 90 seconds

after the first stage.

Heat, 3rd Stage (Y1,Y2,W) Dual Capacity Units

The hot water pump is de-energized which directs all heat

to satisfy the thermostat. The 1st stage of resistance heat is

energized 10 seconds after “W” input, and with continuous

3rd stage demand, the additional stages of resistance heat

engage 90 seconds after the first stage.

Emergency Heat (W only)

The blower is started on high speed, and the first stage of

resistance heat is energized 10 seconds after the "W" input.

Continuing demand will engage the additional stages of

resistance heat 90 seconds after the first stage.

Cooling Operation

In all cooling operations, the reversing valve directly

tracks the “O” input. Thus, anytime the “O” input is present,

the reversing valve will be energized.

Cool, 1st Stage (Y1,O)

The blower motor and hot water pump are started

immediately, the loop pump(s) is energized 5 seconds after

the “Y1” input is received. The compressor will be energized

(on low capacity for Dual Capacity units) 10 seconds after

the “Y1” input. The ECM blower will operate at 85% of

medium speed if in dehumidification mode.

Cool, 2nd Stage (Y1, Y2, O) Single Speed Units

The blower changes to high speed (85% of high speed if

in dehumidification mode) 15 seconds after the “Y2” input

(ECM only).

Cool, 2nd Stage (Y1, Y2, O) Dual Capacity Units

The second stage compressor will be activated 5 seconds

after receiving a “Y2” input as long as the minimum first

stage compressor run time of 1 minute has expired. The

ECM blower changes to high speed 15 seconds after the

“Y2” input (85% of high speed if in dehumidification mode).

The Comfort Alert will delay the second stage compressor

until 5 seconds after it receives a “Y2” from the board.

Blower (G only)

The blower starts and operates on low speed.

Lockout Conditions

During lockout mode, the appropriate unit and thermostat

lockout LEDs will illuminate. The compressor, loop pump,

hot water pump, and accessory outputs are de-energized.

The blower will continue to run on low speed. If the

thermostat calls for heating, emergency heat operation will

occur.

Comfort Alert lockouts cannot be reset at the thermostat.

All other lockout modes can be reset at the thermostat

after turning the unit off, then on, which restores normal

operation but keeps the unit lockout LED illuminated.

Interruption of power to the unit will reset a lockout

without a waiting period and clear all lockout LEDs.

High Pressure

This lockout mode occurs when the normally closed safety

switch is opened momentarily (set at 600 PSI).

Low Pressure

This lockout mode occurs when the normally closed low

pressure switch is opened for 30 continuous seconds (set

at 40 PSI). A low pressure fault may also be indicated when

a Comfort Alert lockout has occurred.

Freeze Detection (Water Flow)

This lockout mode occurs when the freeze detection

thermistor temperature is at or below the selected point

(well 30°F or loop 15°F) for 30 continuous seconds.

IntelliStart

Some models shall be equipped with an optional

IntelliStart. IntelliStart is a single phase soft starter which

reduces the normal start current (LRA) by 60-70%. This

allows the heat pump to more easily go “off grid.” Using

IntelliStart will also provide a substantial reduction in light

flicker, reduce start-up noise, and improve the compressor’s

start behavior. The IntelliStart is self-calibrating and may

take several starts to optimize the compressor’s starting

characteristics.

Features:

Automatic adjustment of the compressor starting

•

current to the available supply voltage —maintaining

constant starting torque and current.

Supply line impedance monitoring and compensation.

•

Automatic compensation for residual backpressure in

•

the system.

Monitoring of supply voltage while compressor is

•

running to prevent motor stalling, causing excessive

currents, under low voltage conditions.

Light flicker reductions of up to 10:1 over LRA under

•

the same conditions.