24

NSZ/NDZ INSTALLATION MANUAL

Leak Testing

The refrigeration line set must be pressurized and

checked for leaks before purging and charging the unit.

To pressurize the line set, attach refrigerant gauges to the

service ports and add an inert gas (nitrogen or dry carbon

dioxide) until pressure reaches 60 to 90 PSIG. Never use

oxygen or acetylene to pressure test. Use an electronic leak

detector or a good quality bubble solution to detect leaks

on all connections made in the field. Check the service

valve ports and stem for leaks and all connections made in

the field. If a leak is found, repair it and repeat the above

steps. For safety reasons do not pressurize the system

above 150 psi. Purge pressure from line set. The system is

now ready for evacuating and charging.

System Evacuation

Ensure that the line set and air coil are evacuated before

opening service valves to the split unit. The line set must be

evacuated to at least 200 microns to remove the moisture

and air that may still be in the line set and coil. Evacuate

the system through both service ports to prevent false

readings on the gauge because of pressure drop through

service ports.

Charge Amount When Using NAH Air Handler

The Envision Split is shipped with a factory pre-charge. This

volume of refrigerant is not sufficient to run the system and

additional refrigerant must be added. If using an NAH Air

Handler please refer to the Line Set Sizes table for charge

amounts to be added. The “Factory Charge” column is the

charge amount the compressor section/split is shipped

with from the factory. The “Charge Amount with NAH Air

Handler” column is the total amount of charge for the NAH

Air H Compressor section/split. This column does

not factor in additional refrigerant needed for the line set.

The installer of the system must add charge appropriately

for the specific length of the line set. A 3/8 in. liquid line is

calculated at 0.50 oz. of charge per linear foot, and a 1/2

in. liquid line is calculated at 1.0 oz. of charge per linear

foot using R-410A refrigerant. The suction line will not hold

“liquid” and should be ignored for the charge calculation.

Example:

NSZ036/NAH036 with 20 ft. of 3/8 in. liquid

line. Remember that when using the NAH Air

Handler, the column “Charge Amount with NAH

Air Handler” will be used. Now calculate for the

additional 20 ft. line set.

Additional refrigerant to be added = (20 ft. x 0.5 oz.)

= 10 oz.

Solution:

10 oz. should be added to the recommended

charge of 86 oz. found in the “Charge Amount

with NAH Air Handler” column for a total charge

of 96 oz.

Refrigeration cont.

After initial charge, the system should be operated and

the system subcooling and superheat verified to the Unit

Operating Parameters table.

If an air handler manufactured by others is used then

refrigerant should be added to the Envision Split factory

pre-charge. Refrigerant should be added for liquid line

length. This should result in a slightly under-charged

system exhibiting low subcooling and high superheat.

As charge is added, the subcooling should rise and the

superheat should fall.

Charging the System

Charge Method – After purging and evacuating the line set,

fully open the service valves counterclockwise. Add R-410A

(liquid) into the liquid line service port until the pressure

in the system reaches approximately 200 PSIG. Never add

liquid refrigerant into the suction side of a compressor.

Start the unit and measure superheat and subcooling. Keep

adding refrigerant until the unit meets the superheat and

subcooling values on the Operating Parameters tables.

Checking Superheat and Subcooling

Determining Superheat

Measure the temperature of the suction line at the

1.

point where the expansion valve bulb is clamped.

Determine the suction pressure in the suction line

2.

by attaching refrigeration gauges to the Schrader

connection on the suction side of the compressor.

Convert the pressure obtained in Step 2 to the

3.

saturation temperature by using the R-410A Pressure/

Temperature Conversion Chart.

Subtract the temperature obtained in Step 3 from

4.

Step 1. The difference is the amount of superheat for

the unit. Refer to the Operating Parameters tables for

superheat ranges at specific entering water conditions.

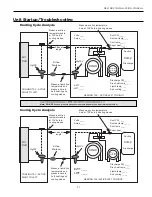

Superheat Adjustment

TXVs are factory set to a specific superheat; however, the

superheat should be adjusted for the application. To adjust

the TXV to other superheat settings:

Remove the seal cap from the bottom of the valve.

1.

Turn the adjustment screw clockwise to increase

2.

superheat and counterclockwise to decrease

superheat. One complete 360° turn changes the

superheat approximately 3-4°F, regardless of

refrigerant type. You may need to allow as much as 30

minutes after the adjustment is made for the system to

stabilize.

Once the proper superheat setting has been achieved,

3.

replace and tighten the seal cap.