30

NSZ/NDZ INSTALLATION MANUAL

High voltage is correct and matches nameplate.

•

Fuses, breakers and wire size correct.

•

Low voltage wiring complete.

•

Piping completed and water system cleaned and

•

flushed.

Air is purged from closed loop system.

•

Isolation valves are open, water control valves or loop

•

pumps wired.

Condensate line open and correctly pitched.

•

Transformer switched to 208V if applicable.

•

DIP switches are set correctly.

•

DHW pump switch is “OFF” unless piping is completed

•

and air has been purged.

Blower rotates freely.

•

Blower speed correct.

•

Air filter/cleaner is clean and in position.

•

Service/access panels are in place.

•

Return air temperature is between 50-80°F heating

•

and 60-95°F cooling.

Check air coil cleanliness to insure optimum

•

performance. Clean as needed according to

maintenance guidelines. To obtain maximum

performance the air coil should be cleaned before

startup. A 10-percent solution of dishwasher detergent

and water is recommended for both sides of coil, a

thorough water rinse should follow.

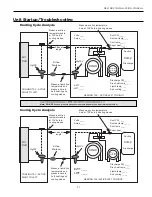

Startup Steps

NOTES:

Complete the Equipment Start-Up/Commissioning

Check Sheet during this procedure. Refer to thermostat

operating instructions and complete the startup procedure.

Initiate a control signal to energize the blower motor.

1.

Check blower operation.

Initiate a control signal to place the unit in the cooling

2.

mode. Cooling setpoint must be set below room

temperature.

First stage cooling will energize after a time delay.

3.

Be sure that the compressor and water control valve or

4.

loop pump(s) are activated.

Verify that the water flow rate is correct by measuring

5.

the pressure drop through the heat exchanger using

the P/T plugs and comparing to unit capacity data in

specification catalog.

Check the temperature of both the supply and

6.

discharge water (see Operating Parameters tables).

Check for an air temperature drop of 15°F to 25°F

7.

across the air coil, depending on the fan speed and

entering water temperature.

Decrease the cooling set point several degrees and

8.

verify high-speed blower operation.

Adjust the cooling setpoint above the room

9.

temperature and verify that the compressor and water

valve or loop pumps deactivate.

Unit Startup

Before Powering Unit, Check The Following:

Initiate a control signal to place the unit in the heating

10.

mode. Heating set point must be set above room

temperature.

First stage heating will energize after a time delay.

11.

Check the temperature of both the supply and

12.

discharge water (see Operating Parameters tables).

Check for an air temperature rise of 20°F to 35°F

13.

across the air coil, depending on the fan speed and

entering water temperature.

If auxiliary electric heaters are installed, increase

14.

the heating setpoint until the electric heat banks

are sequenced on. All stages of the auxiliary heater

should be sequenced on when the thermostat is in

the Emergency Heat mode. Check amperage of each

element.

Adjust the heating setpoint below room temperature

15.

and verify that the compressor and water valve or loop

pumps deactivate.

During all testing, check for excessive vibration, noise

16.

or water leaks. Correct or repair as required.

Set system to desired normal operating mode and set

17.

temperature to maintain desired comfort level.

Instruct the owner/operator in the proper operation of

18.

the thermostat and system maintenance.

NOTES:

Be certain to fill out and forward all warranty

registration papers.

Final Evaluation

After the initial check of superheat/subcooling values

in the heating mode, shut off the unit and allow it to sit

3 to 5 minutes until pressures equalize. Restart the unit

in the cooling mode and check the values against those

in the Operating Parameters tables. If the unit performs

satisfactorily, charging is complete. If the unit does not

perform to specifications, the charge may need to be

readjusted until the values are close. Adding refrigerant will

increase subcooling. Recovering some of the refrigerant

will decrease subcooling and increase superheat. If the

superheat/subcooling values are still not close to the

specifications in the Operating Parameters tables, analyze

refrigerant circuit operation.