7

NSZ/NDZ INSTALLATION MANUAL

Coil uses a TXV. No capillary or fixed orifice systems

•

should be used

A life expectancy of more than 7 years remaining for the

•

air handler and components

Flush air coil and line set

•

When utilizing the existing air coil or line set, only flushing

compounds that vaporize should be used; which means

they are packaged in a pressurized disposable cylinder. It is

preferable to use a flushing agent that removes oil, water,

and acid, plus, is biodegradeable and non-toxic. The flushing

agent should be safe to use with both HCFC and HFC

refrigerants. Once a flushing agent has been selected, follow

the instructions provided with the product.

The first step should be purging the lines or air coil with

nitrogen. Purging with nitrogen first will remove some of

the particulate and residual oil which will allow the flushing

agent to work better. Never blow the flushing agent

through a compressor, filter drier, or txv as it will cause the

components to fail.

When flushing is complete and the final system is assembled,

an acid check should be preformed on the system. Acid test

kits are available from most HVACR distributors.

Connection to Air Coil

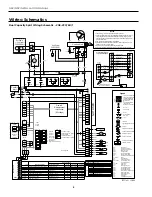

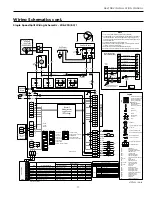

Figures 1 and 2 illustrate typical Envision Split installations.

Reference the Line Set Sizes table for typical line set

diameters and maximum length. Line sets over 60 feet are

not recommended. If the line set is kinked or deformed

and cannot be reformed, the bad section of pipe should be

replaced. A restricted line set will affect unit performance.

As in all R-410A equipment, a reversible liquid line filter

drier is required to insure all moisture is removed from the

system. This drier should be replaced whenever “breaking

into” the system for service. All line sets should be insulated

with a minimum of 1/2 in. closed cell insulation. All exterior

insulation should be painted with UV resistant paint or

covering to ensure long insulation life.

Air Handler Installation

Air handlers used with dual capacity units must be capable

of operating with a minimum of 2 blower speeds. Refer to

the manufacturer’s instructions for the blower coil unit for

details on installing the air handling portion of the system.

All blower coil units/air coils must be installed as specified

by the manufacturer’s installations instructions. However,

the following recommendations should be considered to

minimize noise and service problems.

An air filter must always be installed upstream of the air coil

on the return air side of the air handler or furnace. If there

is limited access to the filter rack for normal maintenance,

it is suggested that a return air filter grille be installed. Be

sure that the return duct is properly installed and free of

leaks to prevent dirt and debris from bypassing the filter and

plugging the air coil.

Ensure that the line set size is appropriate to the capacity of

the unit (refer to Line Set Sizes table). Line sets should be

routed as directly as possible, avoiding unnecessary bends

or turns. All wall penetrations should be sealed properly. Line

set should not come into direct contact with water pipes,

floor joists, wall studs, duct work, floors, walls and brick.

Line set should not be suspended from joists or studs with a

rigid wire or strap which comes into direct contact with the

tubing. Wide hanger strips which conform to the shape of

the tubing are recommended. Isolate hanger straps from line

set insulation by using metal sleeves bent to conform to the

shape of insulation. Line set insulation should be pliable, and

should completely surround the refrigerant line.

NOTES:

Improper installation of equipment may result in

undesirable noise levels in the living areas.

Disconnect

Thermostat Wire

From Air Handler

Vibration Absorbing Pad or Air Pad

P/T Plugs

Water Out

Water In

Lineset To

Air Handler

Insulated Suction Line

Supply

Duct

Wire To

Thermostat

Return

Duct

Condensate Drain

(must be trapped)

To Drain

Remote Air Handler

(Maximum Recommended Distance is

60' Between Units)

DHW In

DHW Out

Figure 1: Typical Split System Application with

Remote Blower Coil

General Installation Information cont.