8

NSZ/NDZ INSTALLATION MANUAL

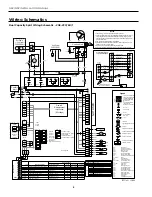

Dual Fuel Systems

Envision units can be connected to fossil fuel furnaces that

include an A-coil or slab coil. Dual fuel installations utilize

the Envision heat pump for heating until the point that aux-

iliary heat is called for on the thermostat. At that point, the

furnace will be enabled and the heat pump will be disabled.

The Envision heat pump provides air conditioning through

the furnace’s refrigerant coils.

Refer to the furnace manufacturer’s installation manual

for the furnace installation, wiring and coil insertion. A

WaterFurnace Dual Fuel thermostat, a field-installed DPST

relay or dual capacity auxiliary heat relay is required. See

Figure 2 for typical Dual Fuel application.

Disconnect

Thermostat

Wire From Furnace

Vibration Absorbing Pad or Air Pad

P/T Plugs

Wire To

Thermostat

Up-Flow

Fossil Fuel

Furnace

Condensate

Drain

(must be trapped)

"A" or

Slab Coil

Supply Duct

Air Temperature Limit Switch -

to prevent compressor operation

when entering air is greater than

90°F.

Water Out

Water In

Lineset To Air Handler

Insulated

Suction Line

DHW In

Return

Duct

DHW Out

Maximum Recommended Distance

is 60' Between Units

Figure 2: Typical Split System Heat Pump Coil Add-On

Fossil Fuel Furnace

In add-on Envision Split applications, the coil should be

located in the supply side of the furnace to avoid con-

densation damage to the furnace heat exchanger. A high

temperature limit should be installed upstream of the coil

to de-energize the compressor whenever the furnace is

operating. Without this switch, the Envision Split will trip

out on high pressure. A dual fuel thermostat can remove

the Y1 and Y2 calls when a W call is energized to allow gas

furnace backup on an Envision Split application. Refer to

thermostat wiring diagram for details.

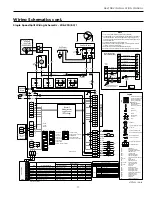

General Installation Information cont.