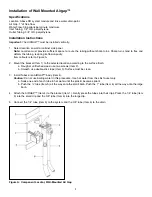

Installation of Drain Saddle Assembly

The system comes supplied with a drain saddle and mounting

hardware which fits around a standard 1½"

O.D.drain pipe (See Figure 4).

a. The saddle should be installed above the trap and on the

vertical or horizontal tailpiece. It should never be placed

close to the outlet of a garbage disposal (See Figure 5).

b. Position saddle assembly on drain pipe to allow adequate

space for drilling through pipe. If possible, angle the drain

saddle fitting toward spigot location.

c. Tighten the drain saddle screws evenly and firmly so a

good seal is made. Avoid over tightening.

d. Drill a 5/16" hole in the drain pipe through the drain fitting

opening. Support the drain against drilling pressure.

e. Insert black drain line tubing into compression nut and

tighten.

NOTE: Some state or local codes may require that the drain saddle be served by a trap other than the

one serving the garbage disposal. Before making a connection as shown in Figure 4, please check with code authorities.

Figure 4 - Drain Saddle Assembly

7

Installation of Feed Water Assembly

The system comes supplied with a saddle-type valve with mounting hardware and is intended to be used

on 3/8" to 1/2" copper tubing cold water supply line. NOTE: It is not to be used on flex lines.

a. Turn off cold water valve under the sink or main valve for the house.

b. Slide the clamp over the copper tubing and tighten the bottom screw firmly to hold the clamp in position.

(See Figure 3a & 3b)

c.

Slide brass nut, plastic sleeve and tube insert on to the green 1/4" plastic tubing and thread onto valve outlet.

d. Pierce the copper tubing by turning the needle valve handle (clockwise) until it is firmly seated. The valve is closed in

this position.

e. Turn on main supply valve to pressurize cold water line. Immediately check for any signs of leaks.

f.

When ready to supply water to the system, turn valve handle (counter-clockwise) until fully open.

Figure 3a

Feed Water Assembly

Figure 3b

Summary of Contents for E50TFC-3NSF

Page 20: ...17 ...

Page 21: ...18 Reverse Osmosis Drinking Water System Flow Diagram all models ...

Page 23: ...20 ...