WL2FLT

Manual Page 14

–

Revision 10-26-2021

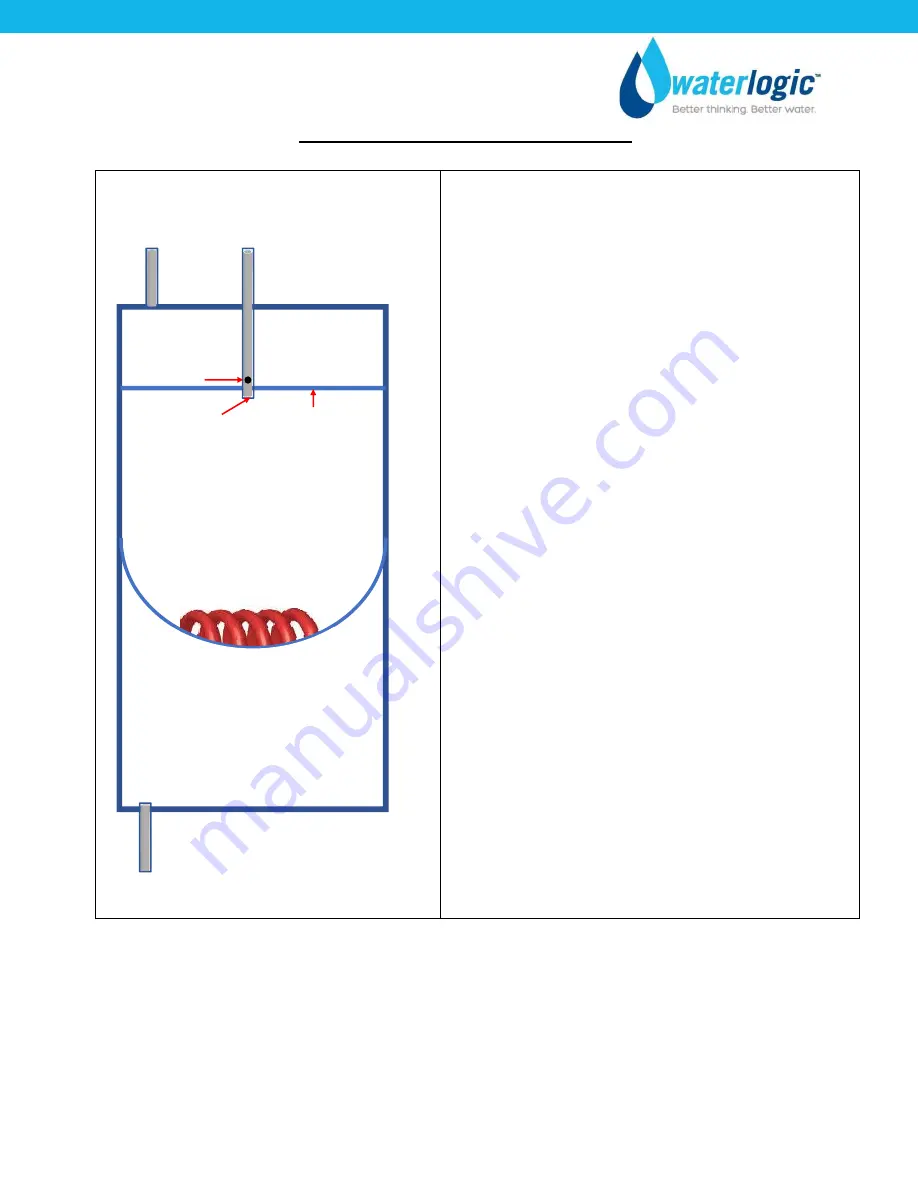

HOT TANK PRINCIPLES OF OPERATION

All

Waterlogic

Hot Tanks have a built-in Vent or

Expansion Chamber in the top of the tank except for

WL270 (GF) units.

The Vent Chamber allows for expansion of the water

when it is heated.

The chambers are separated by a welded-in tank

baffle.

Water always flows into the bottom of the tank and

out the top to the faucet.

The hot tank outlet tube has a restrictor in its base.

This ensures the reservoir is always full by allowing

more water in than out.

There is a small hole in the side of the tank outlet tube

that allows air and water to pass into the vent

chamber as it is heated.

Water in the vent chamber is suctioned back through

the outlet tube vent hole when water is dispensed.

Expansion of water as it is heated in the reservoir will

push the water out the faucet when the outlet tube

vent hole becomes plugged with debris or scale.

The small Outlet Vent Hole is susceptible to scale build

up and is a key indicator that descaling is required.

It is critical to descale the hot tank through the vent

line and outlet line on a regular basis to prevent this

problem.

Descaling through the inlet and/or outlet lines only

will not clean the vent chamber and outlet vent hole

properly.

Vent Outlet

Hot Tank Outlet

To Faucet

Outlet Vent

Hole

Expansion

Chamber

Outlet

Restrictor

Tank Baffle

Heater Element

Hot Tank Inlet