WL3 FX

Manual

Page 70 - Revision: 7-27-2022

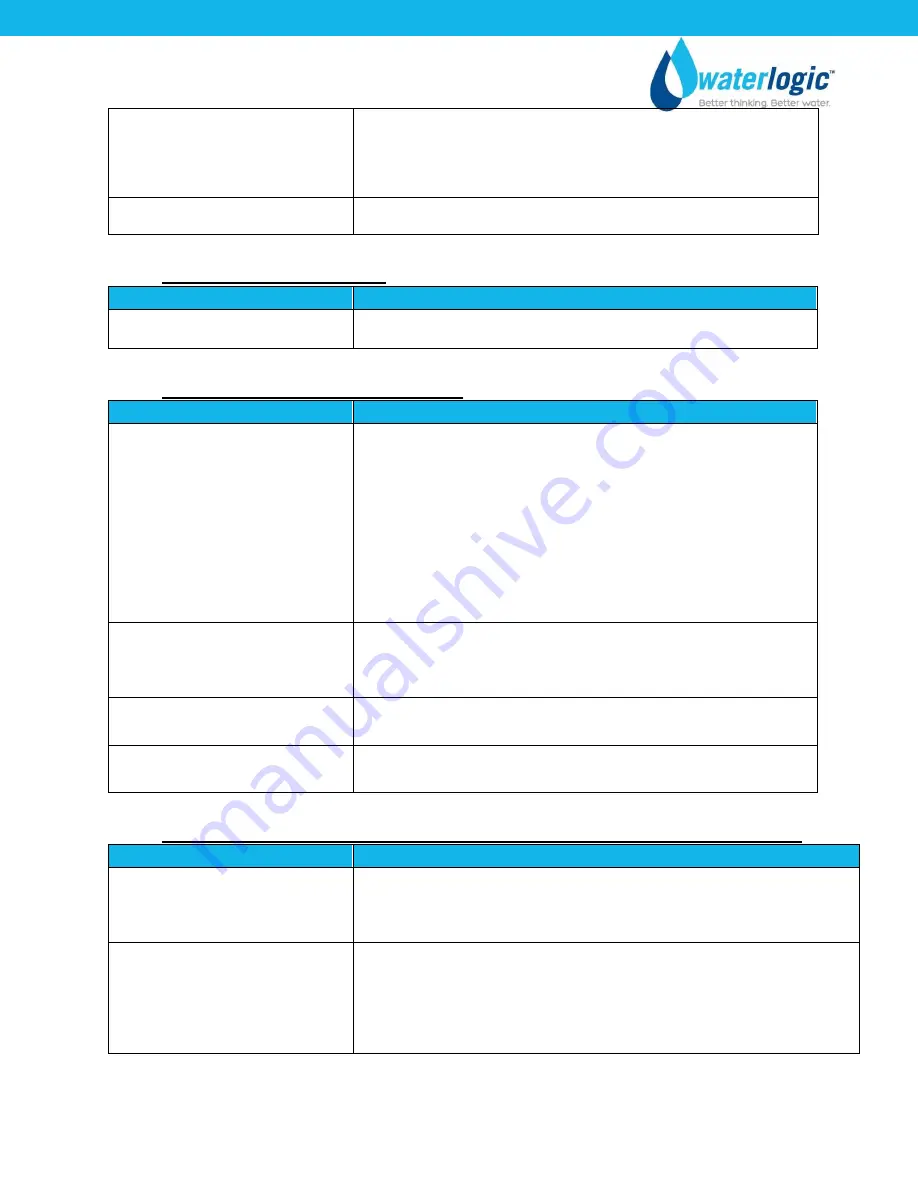

Hot and Cold Solenoid

connections into the Display

PCB are loose.

Turn power off; unplug the unit and visually inspect solenoid

connections into the Display PCB. Verify the soldering points

on connections are secure into the board. Remove the PCB

to inspect the front of the board.

Exhausted Filter

Replace filters as needed.

3.

Steady Drip Out of Faucet

Possible Reason

Solution

Debris in Solenoid

Inspect Solenoid for debris and clean out as needed.

4.

Irregular / Intermittent Dispensing

Possible Reason

Solution

Too much water pressure.

Recommend 40 to 60 psi for

WL3 FX

Water Treatment

System

to operate properly.

Check water pressure at the inlet bulkhead with a water

pressure gauge.

Additional method of verification is to turn off water to unit

and press the dispense button. Does the solenoid open

without water pressure to the unit? Listen for solenoid to

activate, not button “click”.

Adjust water pressure to 40-60 psi.

Loose or bad connection on

the Front Dispensing PCB or

Solenoid Connector

Check that they are connected properly and tightened.

Solenoid

If both the Water Pressure and PCB have been ruled out,

then it is the Solenoid. Replace Solenoid.

Dispensing button is broken on

PCB

Check PCB for loose or damaged button. Replace PCB as

necessary.

5.

Small Amount of Water Periodically Dispenses from Faucet Automatically

Possible Reason

Solution

Cold or Hot Water Solenoid

Valve malfunction`

Inspect valve components for proper function. Replace as

necessary.

Obstruction in Solenoid

housing is preventing proper

sealing of component

Pre-determine whether water being dispensed is Hot / Cold.

Isolate the water supply; push the DISPENSE button to release the

line pressure, and remove the coil affixed to the Solenoid stem.

Remove the stem from the solenoid housing and allow water from

the tank to flush out the contaminate(s).