WL800 Manual

Page 63 – Revision 12-11-2018

FAULT CODE INDEX

1. UV LED Blinking – UV Error

2. Heating and Service LED Blink Simultaneously – Hot Water Sensor Error

3. Chilling and Service LED Light Blink Simultaneously – Cold Water Sensor Error

4. Heating and Service LED Alternate Blinking –Low Water Level Error

5. Chilling and Service LED Alternate Blinking – Full Water Level Error

6. Heating, Chilling and Service LED Sequentially Blink

7. Service LED is On – Leak Detection Probe Has Detected Water

UV LED Blinking – UV Error

Possible Reason

Solution

UV Lamp or Pump is Not

Operational

Check Connections to UV Lamp / Pump Assembly. Replace

UV Lamp / Pump Assembly as needed.

Heating and Service LED Blink Simultaneously – Hot Water Sensor Error

Possible Reason

Solution

Sensor not connected or is not

operating within set

parameters

1.

Check connection to Hot water sensor.

2.

Check OHMS reading – above 900K indicates open

sensor. Below 5.2K indicates sensor short.

Replace Hot Water Sensor.

Chilling and Service LED Light Blink Simultaneously – Cold Water Sensor Error

Possible Reason

Solution

Sensor is not connected or is

not operating within set

parameters

1.

Check connection to Cold Water Sensor.

2.

Check OHMS reading – above 690K Indicates Open

Sensor, below 7.3K indicates Sensor Short.

Replace Cold Water Sensor.

Summary of Contents for WL800 - MAX II

Page 44: ...WL800 Manual Page 44 Revision 12 11 2018 WL800 EXPLODED VIEW AND PARTS LIST...

Page 52: ...WL800 Manual Page 52 Revision 12 11 2018 CABLE SPECIFICATIONS...

Page 53: ...WL800 Manual Page 53 Revision 12 11 2018...

Page 54: ...WL800 Manual Page 54 Revision 12 11 2018...

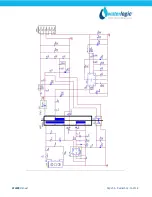

Page 55: ...WL800 Manual Page 55 Revision 12 11 2018 WL800 CIRCUIT DIAGRAMS MAIN PBA...

Page 56: ...WL800 Manual Page 56 Revision 12 11 2018...

Page 57: ...WL800 Manual Page 57 Revision 12 11 2018 FRONT PBA...

Page 58: ...WL800 Manual Page 58 Revision 12 11 2018 PBA LOCATION DIAGRAM MAIN PBA...

Page 59: ...WL800 Manual Page 59 Revision 12 11 2018...

Page 60: ...WL800 Manual Page 60 Revision 12 11 2018...

Page 61: ...WL800 Manual Page 61 Revision 12 11 2018 SMPS...

Page 62: ...WL800 Manual Page 62 Revision 12 11 2018 SMPS...

Page 65: ...WL800 Manual Page 65 Revision 12 11 2018 COLD WATER TROUBLESHOOTING COLD WATER MALFUNCTION...

Page 66: ...WL800 Manual Page 66 Revision 12 11 2018 COLD WATER MALFUNCTION continued...

Page 67: ...WL800 Manual Page 67 Revision 12 11 2018 HOT WATER TROUBLESHOOTING HOT WATER MALFUNCTION...

Page 68: ...WL800 Manual Page 68 Revision 12 11 2018 HOT WATER MALFUNCTION continued...

Page 69: ...WL800 Manual Page 69 Revision 12 11 2018 POWER TROUBLESHOOTING POWER SUPPLY FAULT...

Page 70: ...WL800 Manual Page 70 Revision 12 11 2018 POWER SUPPLY FAULT continued...

Page 71: ...WL800 Manual Page 71 Revision 12 11 2018 DISPENSE TROUBLESHOOTING DISPENSING MALFUNCTION...

Page 72: ...WL800 Manual Page 72 Revision 12 11 2018 TROUBLESHOOTING DISPENSING MALFUNCTION continued...

Page 73: ...WL800 Manual Page 73 Revision 12 11 2018 UV MODULE TROUBLESHOOTING UV MODULE MALFUNCTION...