Safety

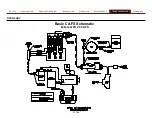

Introduction

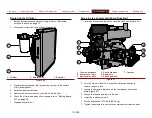

Product Overview

Installation

Operation

Maintenance

Troubleshooting

Warranty

38 | 44

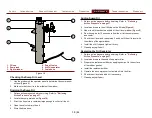

3

2

1

5

4

6

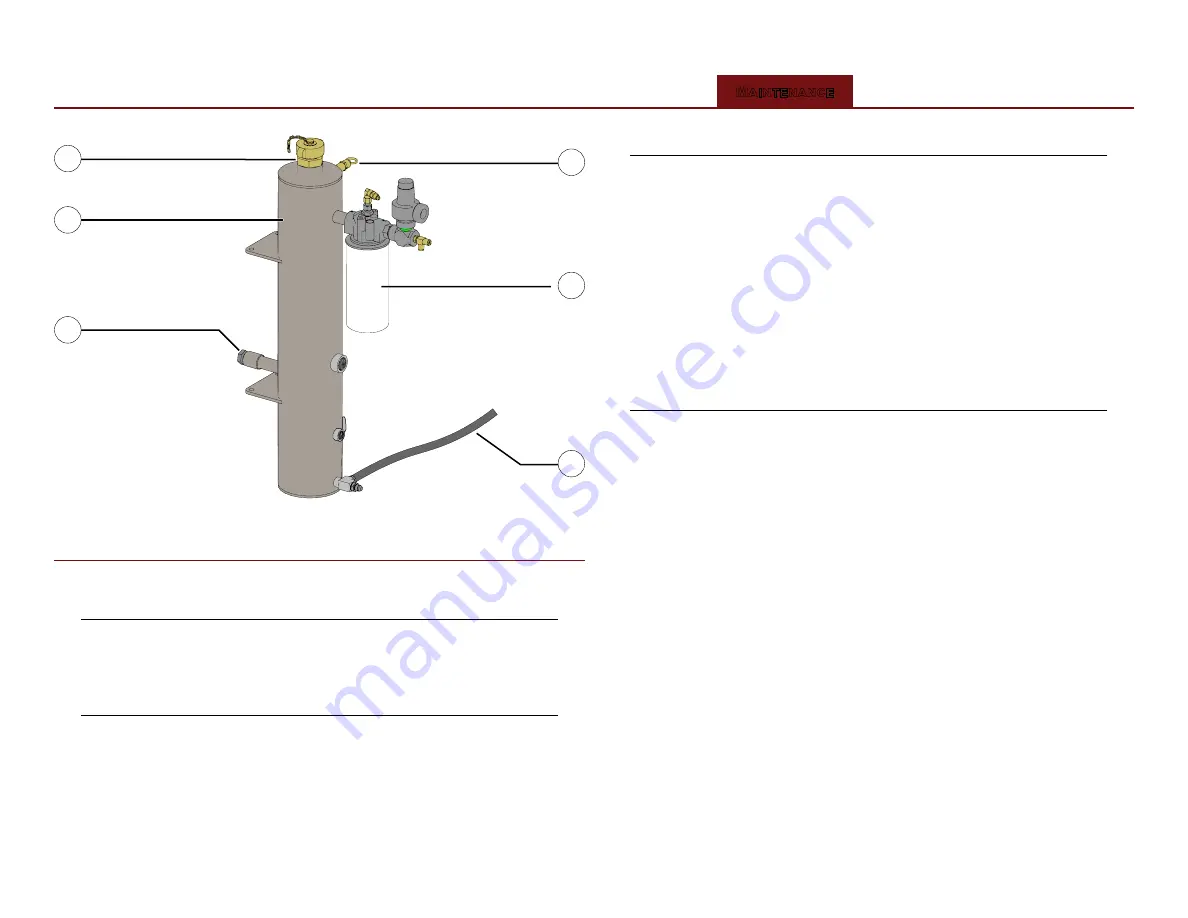

1. Fill cap

2. Sump tank

3. Sight window

4. Pop off valve

5. Air/Oil separator

6. Drain hose

Figure 19

Checking the Sump Oil Level

1. Use the window on the operator panel to determine the compressor

oil level (

).

2. Make sure that the oil is in the middle of the window.

Draining the Sump Oil

1. Relieve airline pressure before servicing. Refer to:

2. Locate the sump drain hose (

).

3. Direct the hose into a container large enough to collect all the oil.

4. Open the valve to drain the oil.

5. Store the drain hose.

Adding Sump Oil

1. Relieve airline pressure before servicing. Refer to:

2.

Locate and remove the oil fill cap on the fill tube (

).

3. Add oil until it reaches the middle of the oil level window (

4.

Run the engine for 10 seconds to flow the oil int the compressor

and cooler.

5. Check the oil level and repeat step 3 and 4 until the oil is level with

the middle of the sight window.

6.

Install the oil fill cap and tighten it firmly.

7. Cleanup any spilled oil.

Replacing the Oil Separator

1. Relieve airline pressure before servicing. Refer to:

2.

Locate and remove the used oil separator filter.

3.

Prepare the replacement filter by applying sump oil to the surface

of the rubber gasket.

4.

Install the replacement filter.

5.

Operate the air compressor to circulate oil into the filter.

6. Check the oil level and add oil if necessary.

7. Cleanup any spilled oil.

Summary of Contents for ECLIPSE CAFSystem 2.0

Page 2: ......