T-360

Page 23 of 35

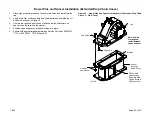

Reassembly of the Cap and Mid-Section

1.

Make sure the face of the mid-section is clean and free of nicks and

burrs.

2.

Clean shims or spacer. If assembly includes a spacer, grease dowel

pin holes in mid-section and install dowel pins. If no spacer is required,

grease dowel pin holes in cap and install dowel pins.

3.

Apply a a thin film of silicone inside bolt hole parttern and outside the

oil port hole as shown in Figure 34.

4.

If no spacer is being used and shims are required, install shims on the

mid-section. Apply a bead of silicone inside the bolt hole pattern on top

of shims.

Figure 34. Mid-Section Assembly

Cap Screw

Dowel Pin

Spacer

(C, D, E & F Drops)

or Cap (B Drop)

Silicone

Mid Section

IL3157

Hex Nut

and Washer

Oil Port Hole,

Transmissions

Built After 2009,

Apply Silicone to

Outside of Hole

5.

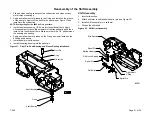

Install cap or cap and spacer to mid-section.

a.

Cap only: Position cap on mid-section and tap dowel pins into mid-

section.

b.

Cap with spacer: Position cap assembly on the dowels previously

installed in the mid-section and tap down into place.

6.

Install appropriate hardware.

7.

Support the mid-section and cap assembly in an upside down position

on suitable supports (

see Figure 3

).

Figure 35. Cap and Mid-Section Assembly

IL2518