T-360

Page 32 of 35

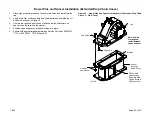

Coupling Shaft Housing Assembly to Case Assembly

The driveline assembly was factory shimmed to limit the axial float of the drive

line. If any of the drive line parts have been changed, it may be necessary to

change the total thickness of shims between the coupling shaft housing and

the transmission case. Shims are color coded for thickness as follows:

.005"

Blue

.007"

Natural

.010"

Brown

The correct thickness of shims can be determined as follows:

1.

Install coupling shaft and housing assembly with no O-ring or shims

between the housing and case. Lightly tighten the cap screws evenly

and tap the end of the coupling shaft with a soft mallet to force the

drive line all the way forward. Do not overtighten causing bending or

breakage of the coupling shaft housing.

2.

Measure the gap between the housing and case in several places to

assure a uniform gap and add .005 in. This will be the total thickness

of shims needed to provide the recommended axial float of .005 - .010

in.

3.

Remove the coupling shaft assembly from the case after measuring

the gap.

NOTE: Field conditions may make it difficult to determine the correct

amount of shims. If in doubt, add another .005 in. shims. No harm will

result from a small amount of additional axial float but bearing life will be

shortened if bearings are excessively preloaded.

4.

Install the correct amount of shims on the coupling shaft housing or if

all original parts are being used, reinstall original shims on coupling

shaft housing.

5.

Coat O-ring with grease and install O-ring on housing.

6.

Install the coupling shaft housing assembly.

7.

Install fasteners.

Figure 50. Assembling Coupling Shaft Housing to Case

Shims

(.005 - .010”)

Axial float

Lock Washer

Hex Hd Screw

Breather

Hose Assembly

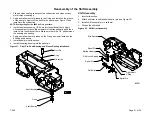

Breather and Hose Assembly Installation

1.

Apply thread sealer to breather and install.

2.

Connect hose assembly from the cap to the mid-section.