T-360

Page 33 of 35

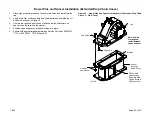

Reassembly of Miscellaneous Items and Accessories

End Yoke Assembly

1.

Slide yoke onto the coupling shaft and drive shafts.

2.

Secure in place using washers and self-locking nuts. Anti-seize should

be applied to the threads before installing a self-locking nut. Do not

reuse self-locking nuts. Torque to 475-525 lb-ft.

3.

Slide yoke on the output shaft.

4.

Secure in place using a self-locking nut. Anti-seize should be applied

to the threads before installing a self-locking nut. Do not reuse self-

locking nuts. Torque to 275-325 lb-ft.

Figure 51. End Yoke Assembly

Coupling and

Drive Shaft

Yokes

Washer

Nut

475-525 lb-ft

Grease Oil Seal

Before Installing Yoke

Output

Shaft

Yoke

Nut

275-325 lb-ft.

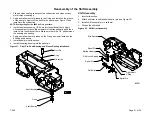

Shift Accessory Assembly

1.

Attach the switch to the switch bracket using a seal and locking nut.

Install the cap.

2.

Set the gasket on the mid-section.

3.

Align the shift arm with the piston in the shift unit and install bracket,

gasket and shift unit to the case with lock washers and hex nuts. Note

that the word “TOP” cast into the shift unit.

4.

Test the shift operations as required.

Figure 52. Pneumatic Shift Assembly

Hex Nut

Lock Washer

Shift Unit

Cap

Locking Nut

Gasket

Switch

Shift Arm

Seal

Gasket

Bracket