2-14

Preparing System Hardware

Priming the sample manager

During the priming process the sample needle fills with solvent, the solvent

changes, and/or air is purged from the lines. You prime the sample needle

and/or sample syringe to accomplish these tasks:

•

Prepare the sample manager for operation

•

Rinse the internal needle, the external piercing needle, and the injection

port

•

Remove bubbles from the lines

Guidelines:

Ensure that the priming solvent is correctly composed and that it

is high in quality and miscible with the other solvents. Use filters in all

solvent reservoirs. Ensure the volumes of solvents are sufficient for priming.

Caution:

Allow the priming sequence to finish. Stopping the priming sequence

can leave strong solvent in the needle, which can affect the chromatography.

Requirement:

The sample manager must be primed before you attempt to

characterize the seal.

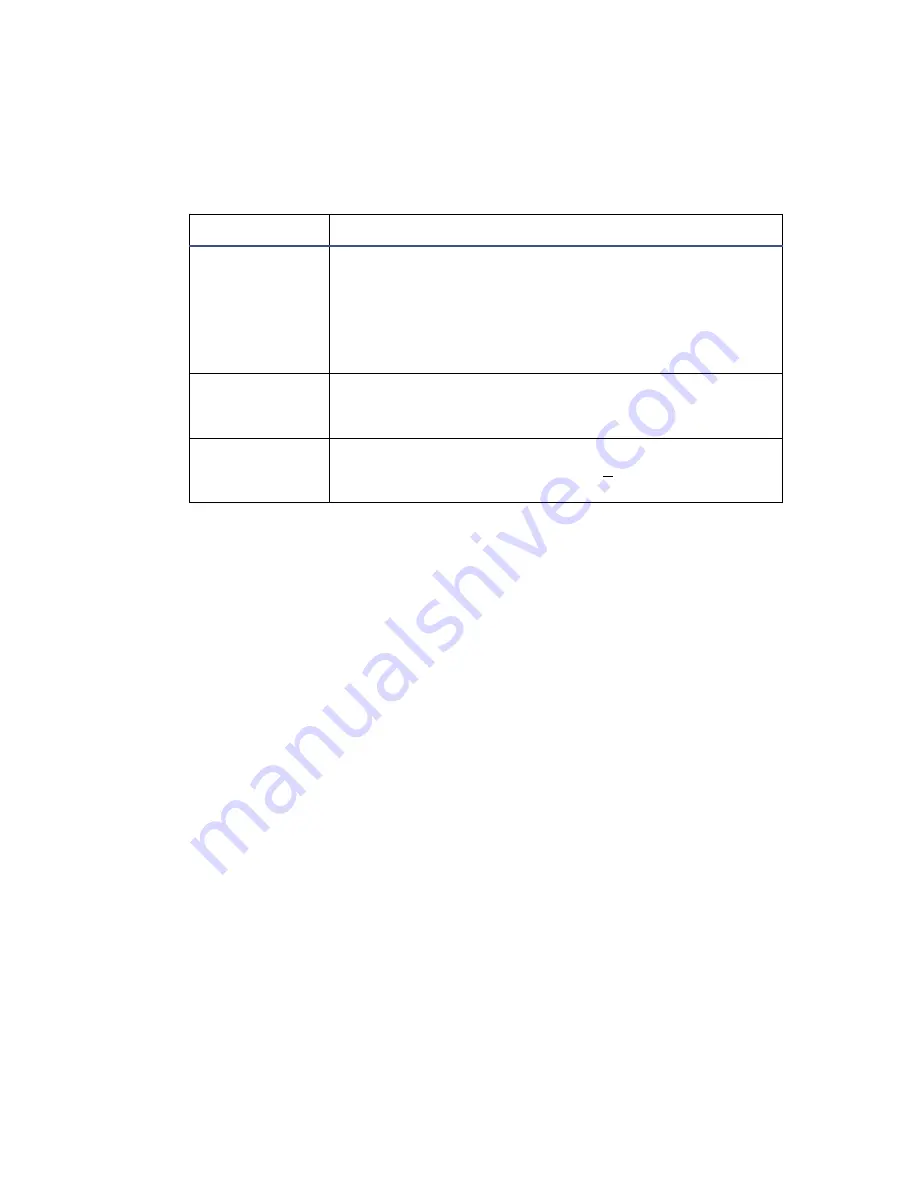

Sample diluent

The weak wash solvent can contact the sample, so match

the weak wash solvent and sample matrix as closely as

possible.

To offset adverse effects on peak shape caused by the

matrix’s composition, adjust the weak wash composition

when using the module in partial loop mode.

Wash volume

ratio (weak to

strong)

Within a method, this should be about 3:1, weak wash to

strong wash, sufficient to ensure the weak wash flushes

the strong from the needle and sample loop.

Cycle times

Higher viscosity wash solvents lengthen wash cycles. For

high-throughput work (cycle times < 1 min), adjust cycle

times accordingly to accommodate the longer wash cycles.

Wash solvent effects: (Continued)

Property

Effect

Summary of Contents for nanoACQUITY UPLC

Page 7: ...vii ...

Page 16: ...xvi ...

Page 20: ...xx Table of Contents ...

Page 32: ...1 12 System Overview ...