December 11, 2015, WAT051512 Rev. B

Page 3

Follow the next procedure if tubing cutting is required to connect the gradient mixer.

To trim the tubing:

1. Using a file with a cutting edge, (such as the file included in the startup tool kit,

part number WAT096146, supplied with each Waters LC System) scribe the

circumference of the tubing at the desired break.

2. Grasp the tubing on both sides of the scribe mark with cloth-covered pliers (to

prevent marring the tube surface) and gently work the tube back and forth until

it separates.

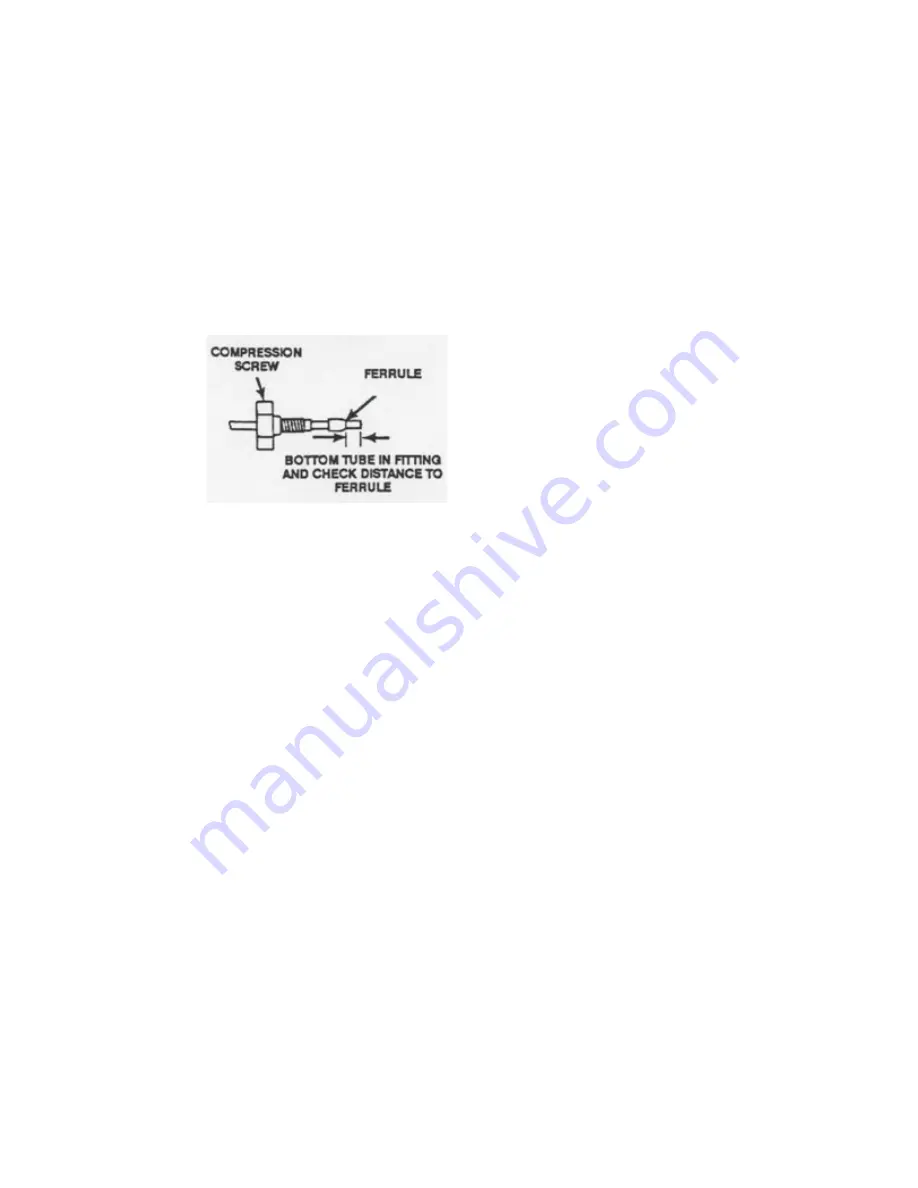

Figure 1–2:

Compression screw and ferrule assembly

3. Slide the compression fitting, followed by the ferrule (large end of the taper

first) over the tube. Bottom the tube in the fitting seat where it will actually be

attached to assure a leak-free connection.

4. Tighten the screw 3/4-turn from finger tight.

Note:

Before running your sample, flush the gradient mixer thoroughly with

selected mobile phase.

Operating the gradient mixer

Assess your system volume variables. For example, leaving a manual injector in the

"inject" position can increase volume by as much as 2 3 mL. Such practices contribute

significantly to solvent changeover time.

Starting up

Flush the Gradient Mixer with at least 10 mL of fresh mobile phase when starting up

your LC system after a brief shutdown (overnight).

Note:

Making a mobile phase changeover also requires flushing the gradient mixer

with at least 10 mL of new mobile phase. However, if the new mobile phase is

immiscible with the old one, flush with 10-15 mL of an intermediate polarity mobile

phase before changing over.

Shutting down

For overnight shut down, be sure to flush salt buffers from the gradient mixer with

water.