December 11, 2015, WAT051512 Rev. B

Page 4

If the gradient mixer is left attached to the LC system during prolonged shutdowns,

thoroughly flush any halogenated mobile phases and/or aqueous mobile phase

(especially salt buffers) from the gradient mixer and store the gradient mixer in an

organic solvent, such as 100% methanol.

If the gradient mixer is removed from the system and stored, follow the steps

outlined above for prolonged storage then displace all solvent within the unit with an

inert gas (nitrogen flush).

Maintaining the gradient mixer

The gradient mixer requires a minimum of maintenance. Follow these procedures to

ensure maximum efficiency.

To maintain the gradient mixer:

1. Be sure to follow the proper start up and shut down procedures outlined in

“Operating the gradient mixer”

.

2. Check your operating backpressure regularly for increases above normal. This is

often caused by a clogged in-line filter and is easily verified by removing the

column and checking the pressure drop across the in-line filter alone. If the

pressure drop is high, replace the filter inside the assembly as follows:

a. Unscrew the two halves of the in-line filter assembly (plumbed before the

gradient mixer as shown in Figure 1:1

remove the filter.

b. Place a new filter in the assembly and hand tighten.

Note:

If the gradient mixer is the cause of the increase, change the direction of

flow. This should dislodge any foreign matter within the narrow passageways

and correct the pressure problem.

Waters limited product warranty

Waters corporation provides this limited warranty (the Warranty) to protect customers

from nonconformity in the product workmanship or materials. The warranty covers all

new products manufactured by Waters and its subsidiaries.

The warranty is as follows:

Waters warrants that all products sold by them will be of good quality and

workmanship. The products will be fit for their intended purpose(s) when used strictly

in accordance with Waters instructions for use during the applicable warranty period.

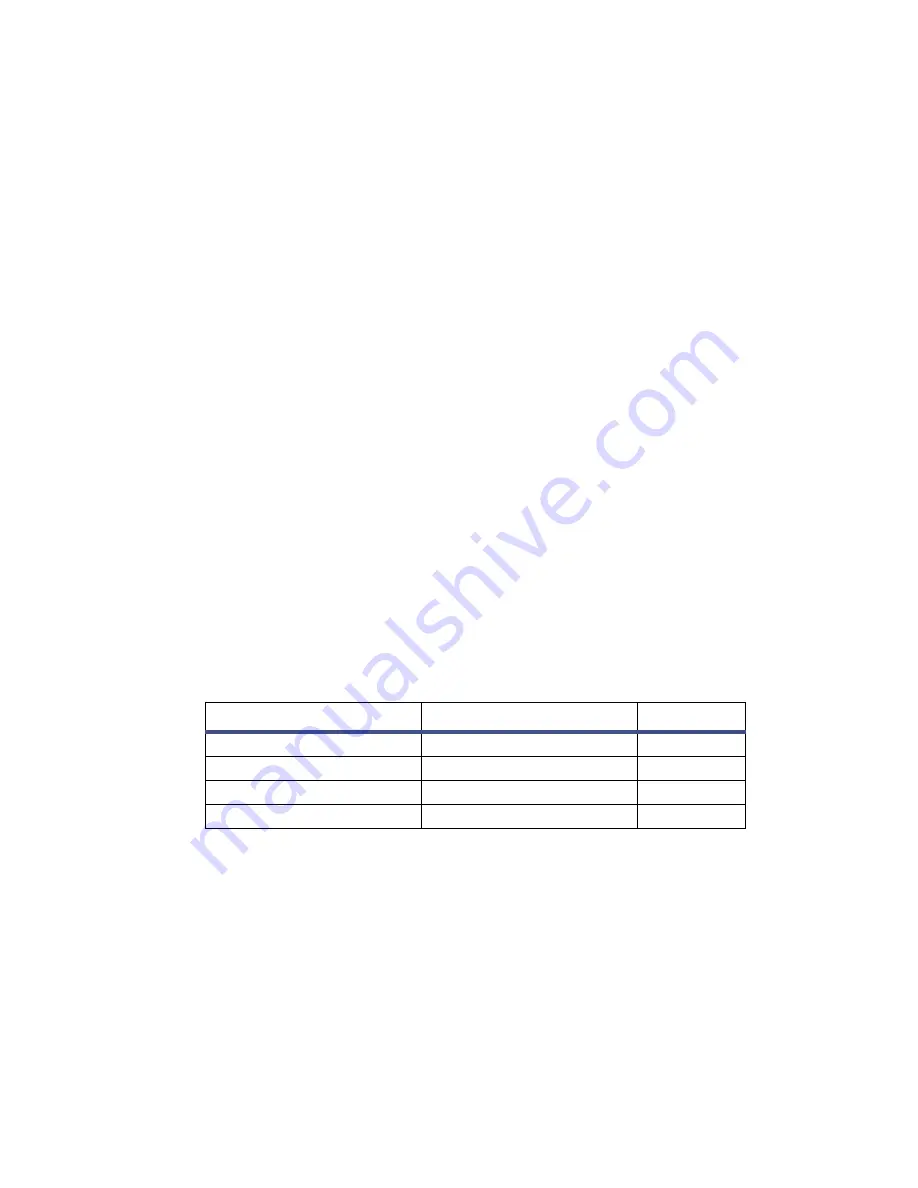

Table 1–2:

Replacement parts

Description

Part number

Quantity

Compression screws

WAT025313

2

Ferrules

WAT022330

2

In-line filter element

WAT088084

1

Tee fitting

WAT075215

1