©

“WATEX” Ltd., Reg. Nr. 40003712811, Ganibu dambis 27 k-5, Riga, LV-1005; Contact information: tel. +371 67381989, e-mail:

info@watex.eu, www.watex.eu

3

GENERAL INFORMATION

We offer water purification technology that will give you the comfort of clean water, save money

and reduce the problems caused by dirty water.

WATEX CMS Twin series (continuous operation) combines the latest technological solutions and is

an effective solution for reducing water hardness, ammonia, iron and turbidity. In addition, the

machine is easy to use, as no special controls are required. The machine will perform its functions if

the requirements given in this technical manual are met.

1.

RELOCATION

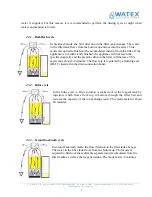

Please note that the water treatment equipment is heavy and fragile, as the fiberglass tank cannot

withstand mechanical shocks. The same applies to the control unit, which has a built-in electronic

board. Any mechanical shock can affect the operation of the machine. It is not recommended to rock

or shake the appliance, as this may cause the layers of filter material inside to mix with each other.

Move the equipment carefully and as vertically as possible!!! If possible, move the equipment on a

cart! If this is not possible, move it with 2 persons. When moving by hand, it is recommended to

hold it at the top behind the control unit housing (where the control unit connects to the tank) and at

the bottom behind the blue fiberglass tank. Do not hold the filter by the lower black tray, as it is not

attached to the tank and may fall out of your hands!