Summary of Contents for AN/PRD-11

Page 2: ......

Page 6: ......

Page 10: ...TM 11 5825 278 12 2 RADIO RECEIVER DIRECTION FINDER SET AN PRD 11 1 0...

Page 18: ......

Page 21: ...1 13 LOCATION AND TM DESCRIPTION OF MAJOR COMPONENTS 11 5825 278 12 2 Continued 1 11...

Page 23: ...TM 11 5825 278 12 2 1 13 LOCATION AND DESCRIPTION OF MAJOR COMPONENTS Continued 1 13...

Page 32: ...TM 11 5825 278 12 2 2 2 RECEIVER CONTROLS INDICATORS AND CONNECTORS 2 2...

Page 33: ...TM 11 5825 278 12 2 2 2 RECEIVER CONTROLS INDICATORS AND CONNECTORS Continued 2 3...

Page 34: ...TM 11 5825 278 12 2 2 2 RECEIVER CONTROLS INDICATORS AND CONNECTORS Continued 2 4...

Page 35: ...TM 11 5825 278 12 2 2 2 RECEIVER CONTROLS INDICATORS AND CONNECTORS Continued 2 5...

Page 36: ...TM 11 5825 278 12 2 2 3 DF PROCESSOR CONTROLS INDICATORS AND CONNECTORS 2 6...

Page 37: ...TM 11 5825 278 12 2 2 3 DF PROCESSOR CONTROLS INDICATORS AND CONNECTORS Continued 2 7...

Page 38: ...TM 11 5825 278 12 2 2 3 DF PROCESSOR CONTROLS INDICATORS AND CONNECTORS Continued 2 8...

Page 39: ...TM 11 5825 278 12 2 2 4 SIGNAL MONITOR CONTROLS INDICATORS AND CONNECTORS 2 9...

Page 40: ...TM 11 5825 278 12 2 2 4 SIGNAL MONITOR CONTROLS INDICATORS AND CONNECTORS Continued 2 10...

Page 41: ...TM 11 5825 278 12 2 2 4 SIGNAL MONITOR CONTROLS INDICATORS AND CONNECTORS Continued 2 11...

Page 42: ...TM 11 5825 278 12 2 2 5 ANTENNA CONNECTORS AND INDICATOR 2 12...

Page 46: ...TM 11 5825 278 12 2 2 9 SITE SELECTION Continued 2 16...

Page 48: ...TM 11 5825 278 12 2 2 9 SITE SELECTION Continued 2 18...

Page 100: ......

Page 107: ...TM 11 5825 278 12 2 2 11 INITIAL ADJUSTMENTS Continued GO ON TO SHEET 3 2 77...

Page 115: ...TM 11 5825 278 12 2 2 12 OPERATING PROCEDURES Continued GO ON TO SHEET 3 2 85...

Page 121: ...TM 11 5825 278 12 2 2 12 OPERATING PROCEDURES Continued 2 91...

Page 123: ...TM 11 5825 278 12 2 2 12 OPERATING PROCEDURES Continued 2 93...

Page 127: ...TM 11 5825 278 12 2 2 12 OPERATING PROCEDURES Continued 2 97...

Page 129: ...TM 11 5825 278 12 2 2 12 OPERATING PROCEDURES Continued GO ON TO SHEET 2 2 99...

Page 184: ......

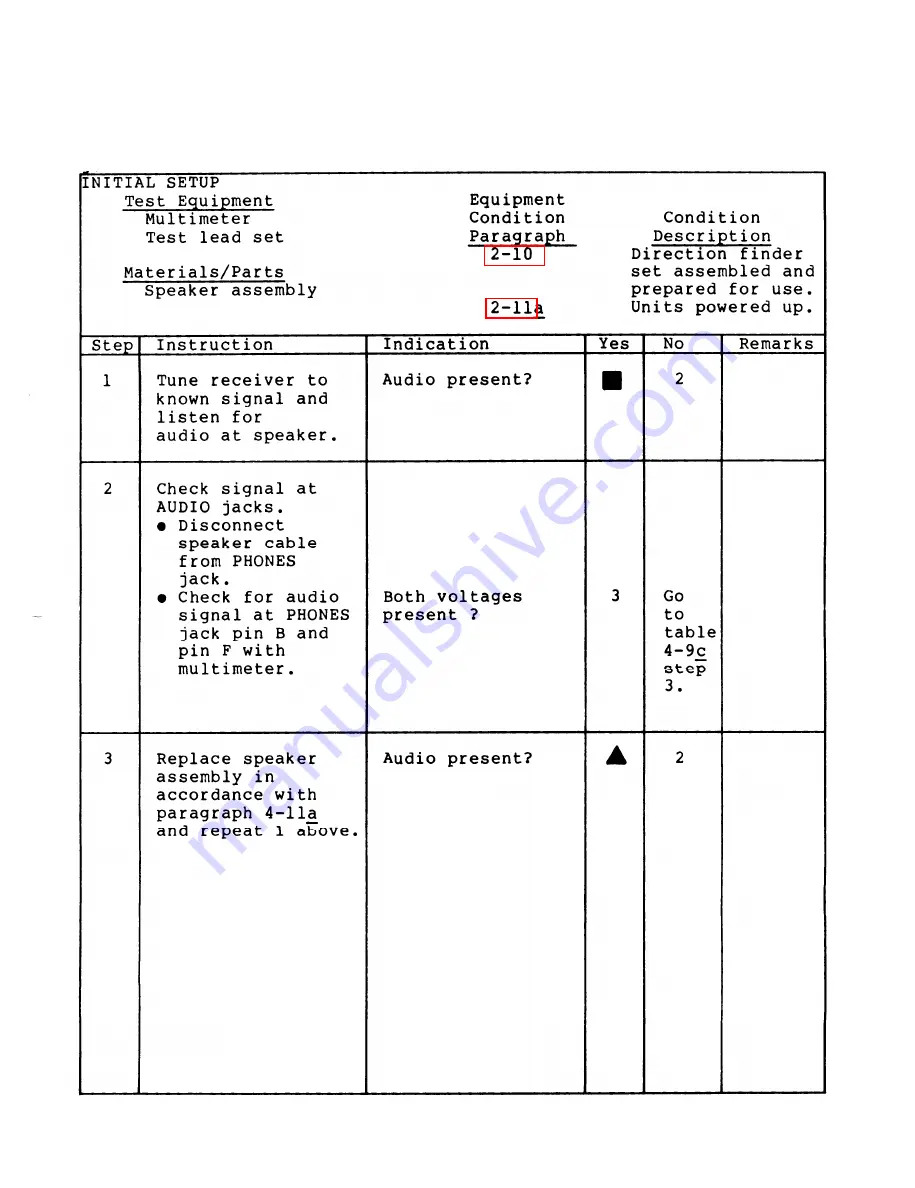

Page 204: ...2 10 2 11a 4 11a TM 11 5825 278 12 2 4 9 TROUBLESHOOTING PROCEDURES Continued k 4 20...

Page 248: ...TM 11 5825 278 12 2 4 11 d MAINTENANCE PROCEDURES Continued 4 64...

Page 251: ...TM 11 5825 278 12 2 4 13 PACKING INSTRUCTIONS Continued 4 67...

Page 254: ......

Page 260: ...TM 11 5825 278 12 2 B 4 Section II MAINTENANCE ALLOCATION CHART...

Page 261: ...TM 11 5825 278 12 2 Section II MAINTENANCE ALLOCATION CHART Continued B 5...

Page 262: ...TM 11 5825 278 12 2 Section II MAINTENANCE ALLOCATION CHART Continued B 6...

Page 263: ...TM 11 5825 278 12 2 Section II MAINTENANCE ALLOCATION CHART Continued B 7...

Page 264: ...TM 11 5825 278 12 2 Section II MAINTENANCE ALLOCATION CHART Continued B 8...

Page 265: ...TM 11 5825 278 12 2 Section II MAINTENANCE ALLOCATION CHART Continued B 9...

Page 266: ...TM 11 5825 278 12 2 Section II MAINTENANCE ALLOCATION CHART Continued B 10...

Page 267: ...TM 11 5825 278 12 2 Section III TOOL AND TEST EQUIPMENT REQUIREMENTS B 11...

Page 268: ...TM 11 5825 278 12 2 Section III TOOL AND TEST EQUIPMENT REQUIREMENTS Continued B 12...

Page 269: ...TM 11 5825 278 12 2 Section IV REMARKS B 13...

Page 270: ...TM 11 5825 278 12 2 Section IV REMARKS Continued B 14...

Page 272: ...TM 11 5825 278 12 2 Section II COMPONENTS OF END ITEM AND BASIC ISSUE ITEMS LIST C 2...

Page 273: ...TM 11 5825 276 12 2 Section III BASIC ISSUE ITEMS C 3 C 4 blank...

Page 274: ...I...

Page 276: ...TM 11 5825 278 12 2 Section II ADDITIONAL AUTHORIZATION LIST D 2...

Page 278: ...TM 11 5825 278 12 2 Section II EXPENDABLE SUPPLIES AND MATERIALS LIST E 2...

Page 286: ......

Page 287: ......

Page 288: ......

Page 289: ......

Page 290: ......

Page 291: ......

Page 292: ......

Page 293: ......

Page 294: ......

Page 296: ......

Page 297: ......

Page 298: ...059582...