1

46°

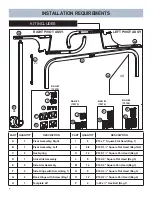

INSTALLATION REQUIREMENTS

KIT INCLUDES

PART

QUANTITY

DESCRIPTION

PART

QUANTITY

DESCRIPTION

A

1

Pivot Assembly, Right

I

8

#10 x 1” Square Flat Head (Bag 1)

B

1

Pivot Assembly, Left

J

8/8

#10 X 1

½

” Square Flat Head (Bag 1&2)

C

2

Gas Spring

K

12

#10 X 1

½

” Square Pan Head (Bag 2)

D

1

Crosslink Assembly

L

8

#10 X 2” Square Flat Head (Bag 3)

E

2

Side Arm Assembly

M

12

#10 X 2” Square Pan Head (Bag 3)

F

2

Side Hinge with Screw (Bag 1)

N

8

#10 X 2

½

” Square Flat Head (Bag 4)

G

2

Back Hinge with Screw (Bag 1)

O

12

#10 X 2

½

” Square Pan Head (Bag 4)

H

1

Template 46°

P

4

¼

-20 x

¾

” Hex Bolt (Bag 1)

A

B

C

D

E

F

G

H

BAG #1

(72574)

BAG #2

(72575)

BAG #3

(72576)

BAG #4

(75104)

P

I

J

J

K

L

M

N

O

2x

2x

RIGHT PIVOT ASSY.

LEFT PIVOT ASSY.

Summary of Contents for COVER CRADLE

Page 12: ...62733 C 04 19...