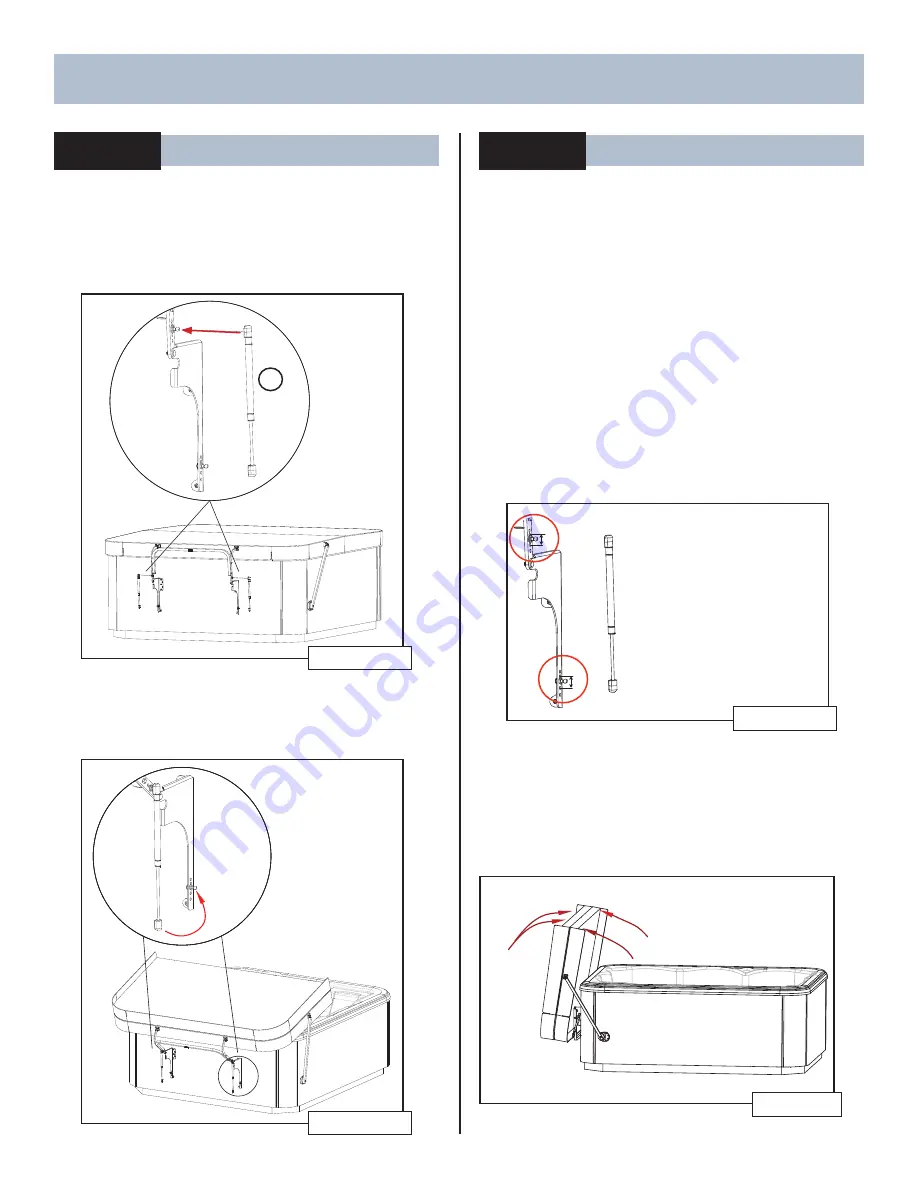

STEP 7

INSTALL GAS SPRING

1. Locate the Gas Springs (C) and snap onto

the upper ball stud (attached to the Pivot Arm

Assembly) with the barrel end of the Gas

Spring up on both sides (Figure 8.1).

Figure 8.1

C

2. Fold Cover in half and pull to position shown

(Figure 8.2). Snap the lower joint of the Gas

Springs onto the lower ball stud (Figure 8.2).

Figure 8.2

STEP 8

ADJUST GAS SPRING

The motion of the cover when opening should be

controlled and smooth rotating to a gentle stop. If

this is how your cover works, skip this step. If the

cover does not fully open or the cover does not

come to a gentle rest then do the following:

a. Remove both Gas Springs by reversing the

order in Step 7. Remove Gas Springs from each

ball stud by placing a fl at blade screwdriver

behind the retaining cup (hold up the clip with

the screwdriver) and pull Gas Spring away.

b. Remove both lower ball studs with a ½” wrench.

Raise or lower ball studs one hole (Figure 9.1)

c. Remove both upper ball studs with a ½” wrench.

Move ball studs in the same direction as in step b.

Move both ball

studs up one hole

to increase force

Move both ball studs

down one hole to

decrease force

Figure 9.1

d. Repeat Step 7

HOW TO OPEN AND CLOSE COVER

Push on either side of the cover to open or close

(Figure 9.2). Cover should come to a gentle rest

with a slight tilt towards the spa.

Figure 9.2

Push this side to open

Push

this

side to

close

PROLIFT III INSTALLATION

9

Summary of Contents for ProLift III

Page 15: ...14 Figure 6 2 PROLIFT III SPACERS BLANK...

Page 16: ...62701 E 04 19...