1

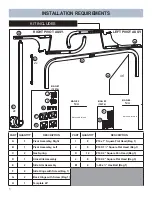

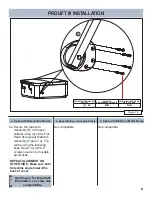

46°

INSTALLATION REQUIREMENTS

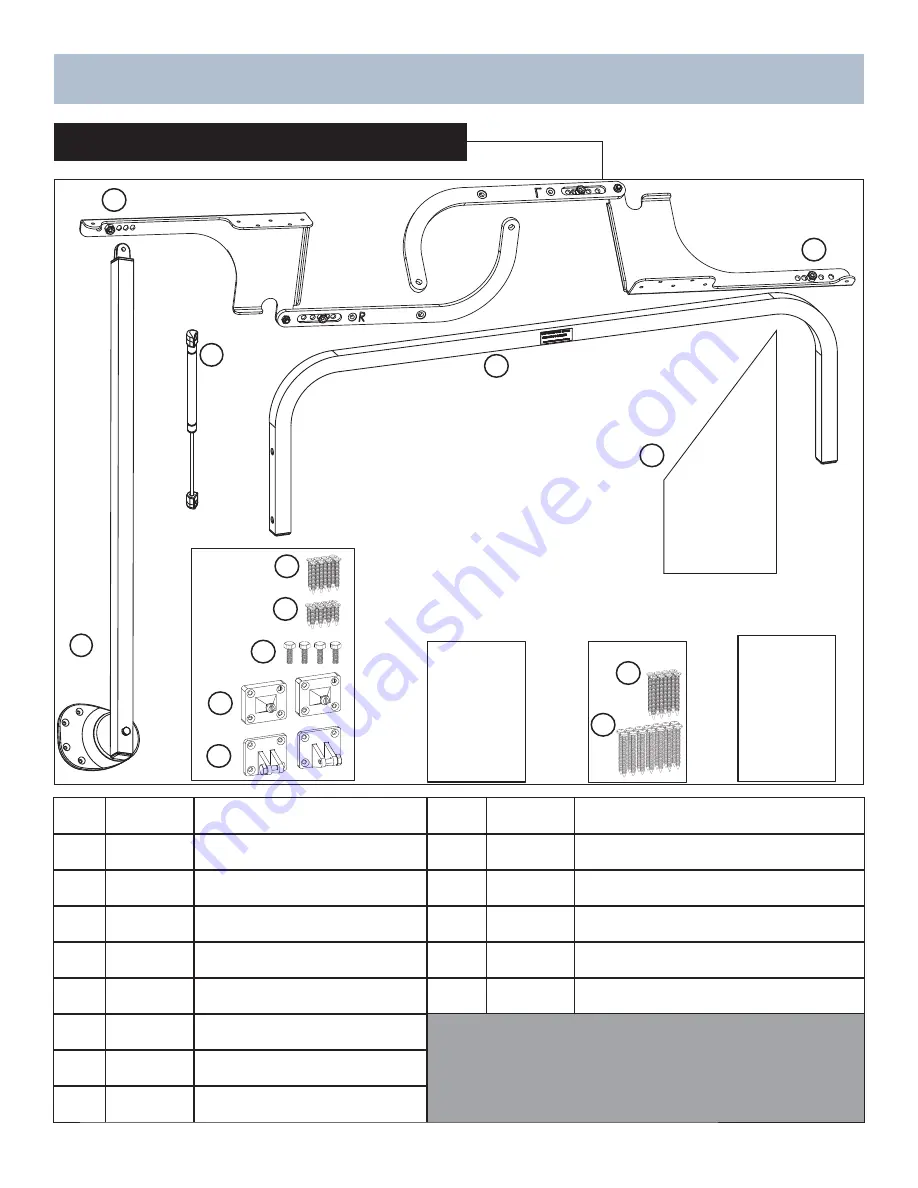

KIT INCLUDES

PART

QUANTITY

DESCRIPTION

PART

QUANTITY

DESCRIPTION

A

1

Pivot Assembly, Right

I

8

#10 x 1” Square Flat Head (Bag 1)

B

1

Pivot Assembly, Left

J

8

#10 X 1

½

” Square Flat Head (Bag 1)

C

2

Gas Spring

K

12

#10 X 2” Square Pan Head (Bag 3)

D

1

Crosslink Assembly

L

8

#10 X 2” Square Flat Head (Bag 3)

E

2

Side Arm Assembly

M

4

¼

-20 x

¾

” Hex Bolt (Bag 1)

F

2

Side Hinge with Screw (Bag 1)

G

2

Back Hinge with Screw (Bag 1)

H

1

Template 46°

A

B

C

D

E

F

G

H

BAG #1

(72574)

BAG #2

BAG #3

(72576)

BAG #4

M

I

J

L

K

2x

2x

RIGHT PIVOT ASSY.

LEFT PIVOT ASSY.

Not used in this kit

N/A

N/A

Not used in this kit

Summary of Contents for ProLift III

Page 15: ...14 Figure 6 2 PROLIFT III SPACERS BLANK...

Page 16: ...62701 E 04 19...