3

STEP 1

INSTALL PREPARATION

Figure 1.1

Front to Back

Warning Label

PROLIFT III INSTALLATION PREPARATION

Figure 1.3

Front or Right

Back or Left

Align

Warning Label

STEP 2

LOCATE PLATES

•

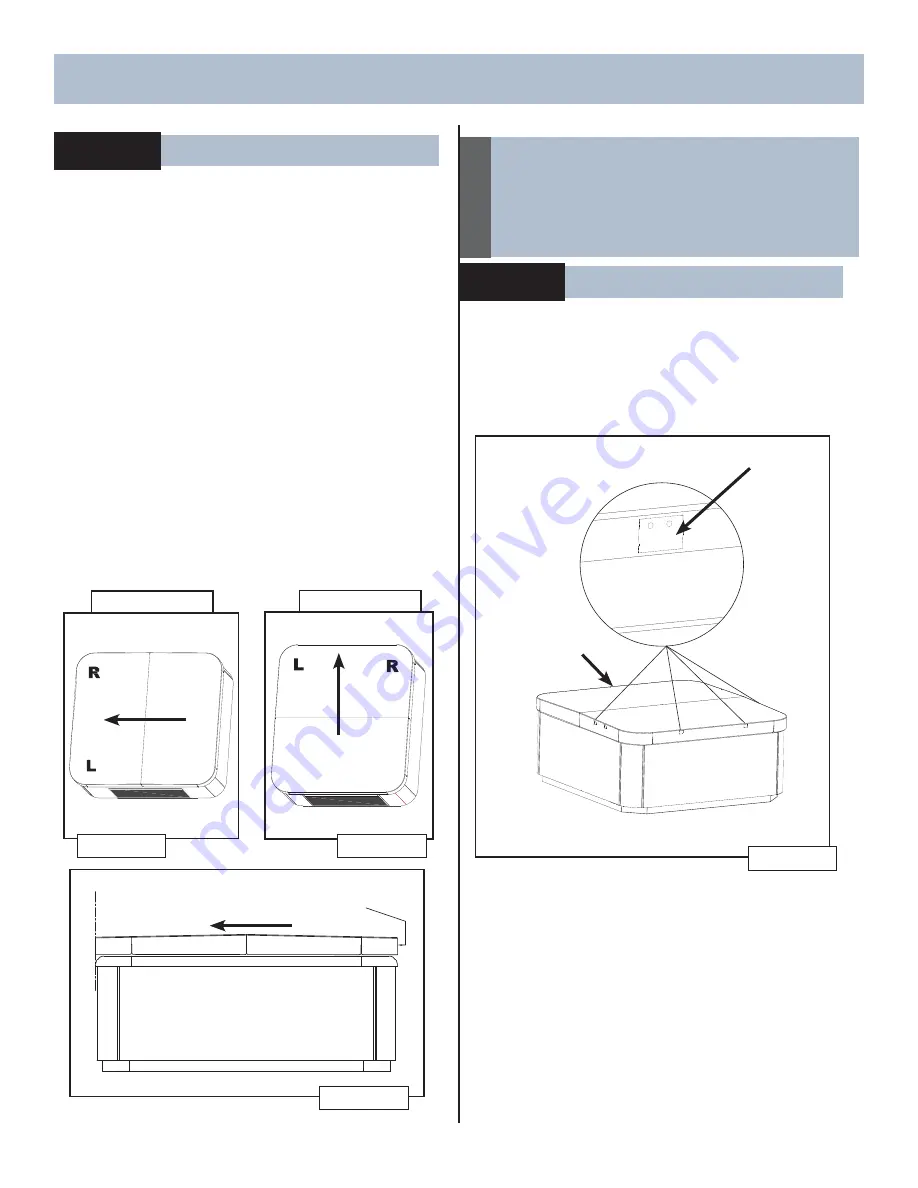

Refer to (Figure 1.1) for the Left and Right cover

lifter set orientation for (Front to Back) cover

confi guration:

•

On a (Front to Back) cover confi guration, the

Left and Right cover lifter set will attach on

back side of spa (Figure 1.1).

•

The cover will fold toward the back side of

spa.

•

Refer to (Figure 1.2) for the Left and Right cover

lifter set orientation for (Side to Side) cover

confi guration:

•

On a (Side to Side) cover confi guration, the

Left and Right cover lifter set will attach on

left side of spa (Figure 1.2).

•

The cover will fold toward the left side of spa.

Figure 1.2

• Align the cover:

• Position the cover evenly on all spa sides

See (Figure 1.3).

Figure 1.4

Warning Label

Hidden Aluminum Plate

Back

Side to Side

W

arning Label

The cover warning label must be facing

the front of the spa on (Front to Back)

confi guration or the right side of spa on

(Side to Side) confi guration (Figure 1.1

and 1.2)

NOTE

Back

Front

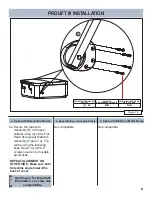

Every Watkins cover has 6 aluminum plates

installed into the foam core hidden beneath the

vinyl on 3 sides of the cover. There are two plates

on the opposite side of the Warning Label and two

on each side of the cover (Figure 1.4).

Only the hidden aluminum plate closest to the

middle of the cover on each side is used for this

cover lifter as well as the two plates in the back

opposite the Warning Label.

There are two predrilled holes on the top of each

plate. Feel around the side of the cover to fi nd the

holes in the plates. Use a fi ne tip marker to mark

the center of the hole for each of the four plates

that will be used (Figure 1.4).

Summary of Contents for ProLift III

Page 15: ...14 Figure 6 2 PROLIFT III SPACERS BLANK...

Page 16: ...62701 E 04 19...