4

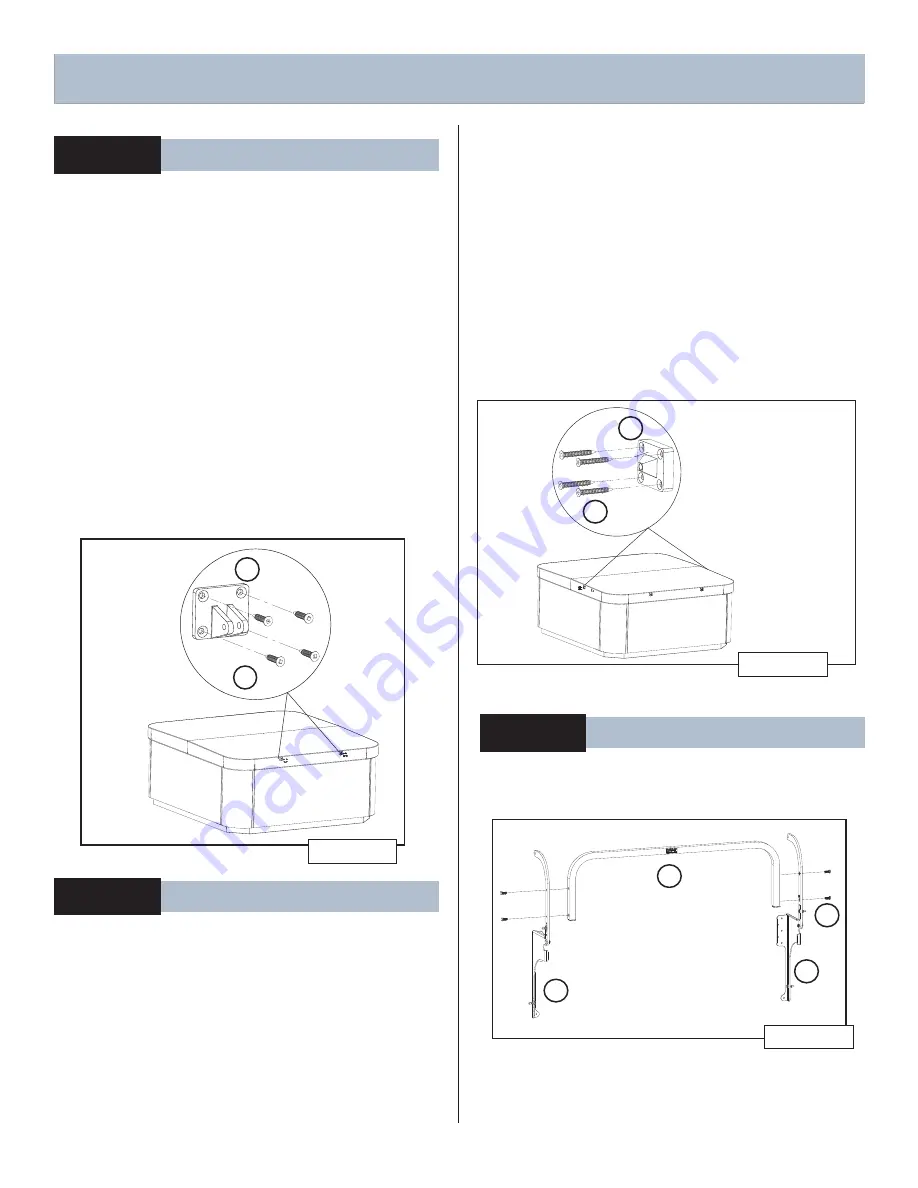

STEP 1

ATTACH BACK HINGES

1. Locate Bag #1, some of the contents will be

used to fasten the Rear Hinges.

REAR HINGES:

2. Line up the top Rear Hinge(G) holes (Figure

2.1) with 2 of the marked holes on the back

side of the cover. Using the cordless drill and

square drive bit fasten the Rear Hinge(G) to

the cover by using two of the #10 x 1”square

(I) Flat Head screws on the top (marked)

holes fi rst. Using the 1/8” drill bit and the

bottom two holes of the Rear Hinge(G), drill

through the hidden aluminum plate followed

by inserting two more of the same screws

in the bottom holes. Repeat procedure for

second Rear Hinge.

1. Locate Bag #1, some of the contents will be

used to fasten the Side Hinges.

SIDE HINGES:

2. Line up the top Side Hinge(F) holes (Figure

2.2) with 2 of the marked holes on one side

of the cover.

3. Using the cordless drill and square drive bit

fasten the Side Hinge to the cover by using

two of the #10 x 1½”square (J) Flat Head

screws on the top (marked) holes fi rst.

4. Using the 1/8” drill bit and the bottom two

holes of the Side Hinge, drill through the

hidden aluminum plate followed by inserting

two more of the same screws in the bottom

holes. Repeat procedure for Side Hinge on

opposite side of the cover.

Repeat procedure for Side Hinge on

opposite side of the cover.

STEP 3

ASSEMBLE CROSSLINK

1. Locate the Right & Left Pivot Assemblies,

Crosslink and (4) ¼”-20 Hex Bolts (Figure 4.1).

Figure 4.1

A

C

4x

B

M

2. Orient (Figure 4.1) on fl oor and attach A and

B to C using (4) ¼”-20 Hex Bolts (M).

PROLIFT III INSTALLATION

Figure 2.1

G

I

4x

STEP 2

ATTACH SIDE HINGES

Figure 3.1

F

J

4x

Summary of Contents for ProLift III

Page 15: ...14 Figure 6 2 PROLIFT III SPACERS BLANK...

Page 16: ...62701 E 04 19...