7

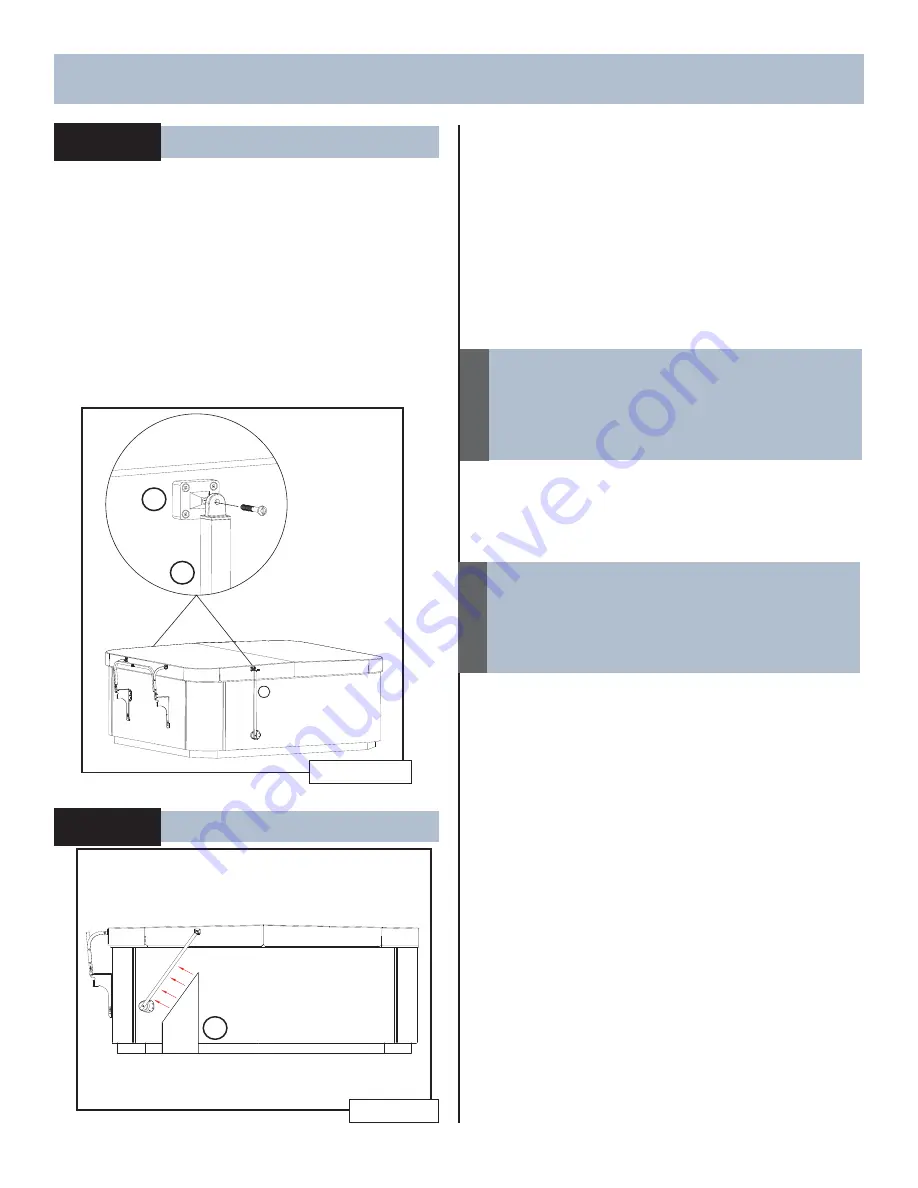

STEP 5

ATTACH SIDE ARM ASSY

1. Remove the single bolt attached to the Side

Hinge (F)(Figure 6.1) on the side of the spa.

Attach the Side Arm Assembly (E) (Figure

6.1) to the Side Hinge (F) (Figure 6.1) using

the single bolt. Repeat on other side of spa.

2. IMPORTANT:

Plastic Bottom (Pivot Bracket) of

Side Arm Assembly (E) must lay fl at against spa

siding.

DO NOT OVERTIGHTEN SCREW or the cover

will bind.

F

Figure 6.1

E

STEP 6

ALIGN SIDE ARM ASSY.

1. Locate the Cardboard Template (H) and place

on ground below Side Arm Assembly (Figure

7.1).

2. Slide Template against Side Arm Assembly,

making sure the entire angle of the Template

touches the Side Arm Assembly (Figure 7.1).

3. Position the Plastic Bottom (Pivot Bracket)

with the holes facing away from the back of

the cover (Figure 7.2).

4. Holding Pivot Bracket in place, mark all 4

holes and pre-drill with 1/8”(3mm) drill bit at a

depth of 1/2”(12.5mm) into spa cabinet.

PROLIFT III INSTALLATION

E

Use the appropriate size screws to secure the

Side Arm Assembly. Please use (Figure 7.2)

and information on

Page 8

of this document to

determine the correct screw size.

NOTE

If Pivot Bracket rests on both the side panel

and corner panel, creating a gap behind the

Pivot Bracket, Pivot Bracket may be rotated

180° and placed onto the corner panel of spas.

NOTE

Figure 7.1

H

46˚

Summary of Contents for ProLift III

Page 15: ...14 Figure 6 2 PROLIFT III SPACERS BLANK...

Page 16: ...62701 E 04 19...