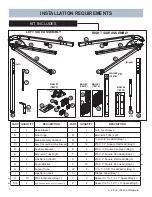

2

Cordless Drill

Flat Head

Screwdriver

7/16” Socket with

Ratchet

Safety Glasses

#2 Square Drive

Bit

1/8” a Drill Bit

Fine Tip Marker

1/2” Wrench

7/16” Wrench

Straight Edge

Ruler 24” - 36”

INSTALLATION REQUIREMENTS

TOOLS REQUIRED

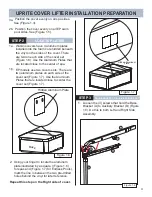

IMPORTANT INFORMATION

• Two technicians are recommended for installation.

• Read all of the instructions thoroughly before performing this installation.

• There must be a minimum of 7” clearance between the wall and the retracting side of the spa for

cover to operate properly and 3” on each side for Side Arm clearance.

• NOTE: Consider spa cover wind skirt length when considering installation of cover lifter.

• The Warning Label is always on the front of the cover; the lifter will attach on either the back side

of the spa or the left side of spa depending on cover confi guration.

• On Endless Pools models the lifter will attach on either the back or front of spa.

• To ensure that the cover seals correctly, the spa must be leveled.

3.175mm

Summary of Contents for UPRITE

Page 15: ...14 NOTES ...

Page 16: ...62732 D 01 20 ...