System Description

•

TrimMaster Overview

Watkiss BookMaster Service Manual - Issue 1 - 14/12/00

7

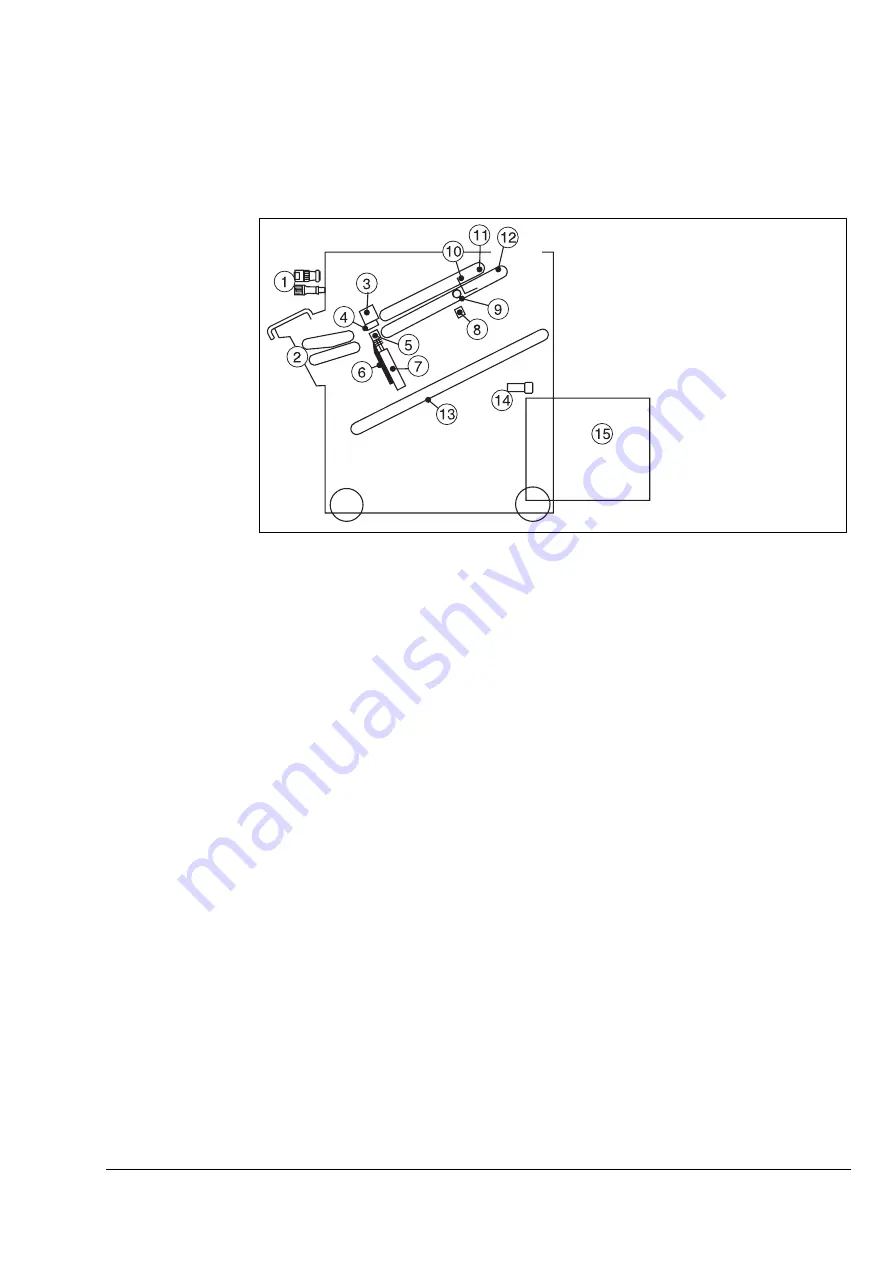

1.4 TrimMaster Overview

The TrimMaster is a separate unit which is designed to integrate with the

BookMaster. Power and communications for the TrimMaster are taken from

two sockets on the BookMaster into an interface PCB. All the components of

the TrimMaster are controlled from this board. The TrimMaster is secured to

the BookMaster by docking hooks.

Figure 1:2 TrimMaster : Overview of key components

Note that the TrimMaster is only compatible with the BookMaster. The Trim-

Master Pro is only compatible with the BookMaster Pro.

TrimMaster Blade:

The TrimMaster has a single blade (6) which is driven up

past an anvil (4) in a scissor action. The book enters the TrimMaster into the

infeed conveyor (2) and then between the blade and anvil. A solenoid, trig-

gered by a signal from the staple sensor in the BookMaster, pushes the paper

stop latch (10) into its vertical position. The latch stops the book in the re-

quired position. The book is then held at the folded edge by a spring tensioned

roller clamp shaft (9) and at the trailing edge by a steel clamp (5) before being

trimmed. A sensor (8) in the conveyor detects the successful passage of the

book and triggers the outfeed conveyor.

TrimMaster Blade Drive:

Drive to the TrimMaster blade is provided by a

motor/gearbox in the base. Power is transferred from the drive motor via a

toothed belt to the clutch and from there to a connection arm assembly. A

crank on the bottom end of each arm converts the rotational drive of the motor

into the lateral movement needed by the blade. The gearbox oil should not re-

quire refilling.

Conveyor:

The motor also drives the TrimMaster conveyor via a chain drive

and clutch. An adjustable tensioner is fitted in the chain drive. The TrimMas-

ter may be manually cycled when performing operations such as blade re-

placement (see section 3.4.1 ‘‘Cycling the TrimMaster by Hand’’).

Conveyor Clamp:

The TrimMaster conveyor clamp rollers hold the spine of

the booklet during trimming. They are pre-set in the factory but are adjustable

if required (see section 3.4.2 ‘‘Conveyor Clamp Adjustment’’).

1. Connections to BookMaster

2. Infeed Conveyor

3. Anvil Clamp Bar

4. Anvil

5. Steel Clamp

6. Blade

7. Bolster

8. Sensor

9. Conveyor Clamp Roller

10.Paper Stop Latch

11.Upper Conveyor

12.Lower Conveyor

13.Waste Conveyor

14.Trim Bin Full Sensor

(TMP only)

15.Trim Bin

Summary of Contents for BookMaster

Page 6: ...c iv Watkiss BookMaster Service Manual Issue 1 14 12 00...

Page 18: ...12 Watkiss BookMaster Service Manual Issue 1 14 12 00 System Description Fuses...

Page 54: ...48 Watkiss BookMaster Service Manual Issue 1 14 12 00 Service Procedures TrimMaster Pro...

Page 56: ...50 Watkiss BookMaster Service Manual Issue 1 14 12 00 Electronics Software Connection Diagrams...

Page 57: ...Electronics Software Connection Diagrams Watkiss BookMaster Service Manual Issue 1 14 12 00 51...

Page 58: ...52 Watkiss BookMaster Service Manual Issue 1 14 12 00 Electronics Software Connection Diagrams...

Page 59: ...Electronics Software Connection Diagrams Watkiss BookMaster Service Manual Issue 1 14 12 00 53...

Page 60: ...54 Watkiss BookMaster Service Manual Issue 1 14 12 00 Electronics Software Connection Diagrams...

Page 61: ...Electronics Software Connection Diagrams Watkiss BookMaster Service Manual Issue 1 14 12 00 55...

Page 62: ...56 Watkiss BookMaster Service Manual Issue 1 14 12 00 Electronics Software Connection Diagrams...

Page 63: ...Electronics Software Connection Diagrams Watkiss BookMaster Service Manual Issue 1 14 12 00 57...

Page 64: ...58 Watkiss BookMaster Service Manual Issue 1 14 12 00 Electronics Software Connection Diagrams...

Page 65: ...Electronics Software Connection Diagrams Watkiss BookMaster Service Manual Issue 1 14 12 00 59...

Page 66: ...60 Watkiss BookMaster Service Manual Issue 1 14 12 00 Electronics Software Connection Diagrams...

Page 67: ...Electronics Software Connection Diagrams Watkiss BookMaster Service Manual Issue 1 14 12 00 61...

Page 127: ......