Description of Operation

8

Plockmatic PowerSquare™ 224 - Service Training Workbook

The PBR5 bridge does not have static elimination bars. Blue, non-conductive

belts and additional anti-static brushes remove the static charge on the paper.

An optical sensor in the bridge infeed sees that a piece of paper has entered the

system. Another optical sensor at the entry to the gathering area sees that the

paper has left the bridge. If the time between the operation of the sensors is

more than a calculated period, a paper jam is indicated. The PSQ sends an

error message to the printer. The print job and the PSQ stop.

3.2

The Gathering Area

When the paper is fed into the gathering area, the paper falls between the

endlays and sidelays. The endlays and sidelays are adjusted by the PSQ

according to the paper size selected. This adjustment is important and

necessary to the quality of the finished book. Adjustments to the sidelays and

endlays are made with two 24V DC electric motors.

The tamper fingers guide smaller sheets of paper to help them drop between

the sidelays and the endlays. The tamper fingers are positioned and operated

by a stepper motor. The lowest position for the tamper fingers is for the smallest

size of paper. The highest position for the tamper fingers is for A3-size (11 x 17")

paper.

An active gate in the sidelay closest to the stitch head jogs the incoming sheets

into a tidy set. When the set is complete, the active gate lifts away to let the set

move to the stitch position.

When a set is printed the printer sends an ‘end of set’ signal to the PSQ, which

starts the PSQ cycle of operation.

The tamper fingers drop and apply pressure to the top of the set, which

removes the air from between the pages. After a standard interval, the tamper

fingers lift and leave the set ready for collection by the shuttle. A rear tamper in

the gathering area prevents sheets from riding-up over the rear pick-up fingers.

3.3

The Shuttle

The set is collected by the shuttle and moved to the 1st stitch position. A cam

mechanism tightens the shuttle pick-up fingers on the set when the shuttle

moves towards the 1st stitch position. The increased hold makes sure the

pages remain in alignment when the set is stitched. The rear or large shuttle

pick-up fingers incorporate rollers to prevent toner deposition that could mark

the covers of the books.

The set is stitched, then moved by the shuttle to the next stitch position. This

process is repeated as necessary to a maximum of 6 stitches. When set to

AUTO, the PSQ automatically calculates the stitch positions. The user can

change the stitch pitch within certain limits. This function can be used to give a

clearance between the stitches and the print on the spine of the book.

Quality Tolerances

Plockmatic PowerSquare™ 224 - Service Training Workbook

41

Copyright © 2016 Watkiss Automation Limited

16.

Quality Tolerances

Power Supply

Adjustable to 200, 208, 220, 230 and 240V

50/60Hz, single phase

Note: startup peak value max 30A. A slow circuit breaker

of minimum 16A is required.

Power

Consumption

standby: 92VA (75W)

in operation: 700VA (500W)

Acoustical Noise

Emission

standby: ambient

in operation: 66 dB (A), peak 87 dB (A)

Approvals

Complies with CE and UL. Conforms to FCC rules Part

15 Class A and VCCI Class A.

Patents

GB.2360013, EP.1138521, US.6692208, JP.5059997

GB.2401820, EP.1479258, US.7325799, JP.4887449

* Standard book is made from 20 sheets of 80gsm bond paper, with 2 stitches.

Production may vary according to operating conditions. In line with a policy of

continual product improvement, the manufacturer reserves the right to alter the

materials or specification of this product at any time without notice.

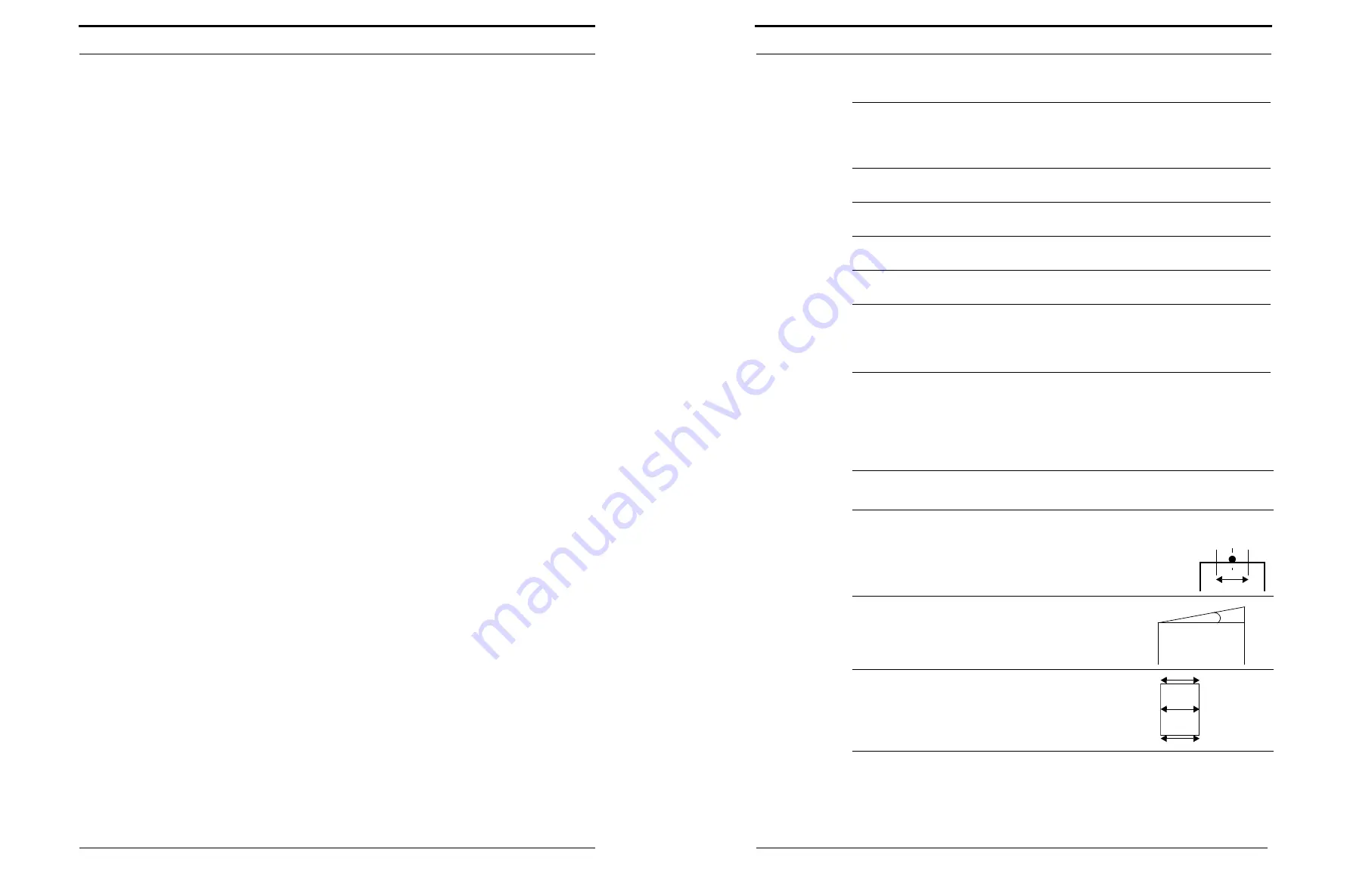

Sheet Alignment

Sheet to sheet: up to 0.5mm

Within set: up to 1.0mm

Accuracy of

stitching and folding

Stitch position: within 0.5mm of the centreline of the

sheet, measured on an un-trimmed book.

Formed spines: Centreline of stitch within

centre 50% of spine width

Un-formed spines: On spine +/- 1mm

Squareness of

folding

From spine to trimmed edge:

within 0.28°

Accuracy of

trimming

Within 1mm (a, b, c)

50%

x

°

spin

e

open edg

e

a

b

c

illustration

shows a book