Calibration, Chapter 5

25

WATLOW Series 733/734 Service Manual

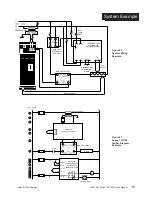

T/C Calibration

Calibration

˜

NOTE:

Before calibration

on an installed

control, make sure

all data and param-

eters are docu-

mented. See Setup,

and Service Tables,

Pages16 and 19.

˜

NOTE:

Always press the

Time key to advance

to the next param-

eter before chang-

ing the calibration

equipment.

˜

Thermocouple Field Calibration Procedure

(Single & Dual Thermocouple Only)

For model #'s:

73XX-1XXX-XXXX

73XX-4XXX-XXXX

Equipment Required:

•

Type "J" Reference Compensator with reference junction at 32°F/0°C

OR

Type "J" Thermocouple Calibrator set at 32°F/0°C.

•

Precision millivolt source, 0-50mV min. range, 0.01mV resolution

Two millivolt sources and two compensators OR two thermocouple calibrators are

required

for dual zone controls.

Setup And Calibration

˜

1. Connect the AC line voltage L1 and L2 to the proper terminals.

2. For Zone 1, connect the millivolt source to Terminal #2 Positive and Terminal #3

Negative on the Series 733/734 terminal strip. Use regular 20-24 gauge wire.

For Zone 2, connect the millivolt source to Terminal #5 Positive and Terminal #6

Negative on the Series 733/734 terminal strip. Use regular 20-24 gauge wire.

3. Apply power to the unit and allow it to warm up for 15 minutes. After warm-up

put the unit in the CAL menu. See the beginning of this chapter.

4. At the CALy parameter, select ALL. At the InLO prompt, enter 0.00 mV from the

millivolt source to the control for each zone. Allow at least 10 seconds to

stabilize. Press the TIme key.

5. At the InHI prompt, enter 50.0mV from the millivolt source, for each zone. Allow

at least 10 seconds to stabilize. Press the Time key.

6. At the tc prompt, disconnect the millivolt source, and connect the reference

compensator or t/c calibrator to Terminal #2 Positive, and Terminal #3 Negative

for Zone 1, and to Terminal #5 Positive and Terminal #6 Negative for Zone 2. If

using a compensator, turn on and short the input wires. If using "J" calibrator,

set to simulate 32°F/0°C. Allow 10 seconds for the control to stabilize.

To conclude the t/c calibration, press the Time key to advance through the

Calibration mode. To continue calibrating your outputs, press the Time key

once. The unit will leave the Calibration mode if 1 minute passes between key

activations and retains all changed values.