Watlow EZ-ZONE

®

ST

•

3

•

Chapter 1 Overview

Chapter 1: Overview

1

The EZ-ZONE

®

ST Provides Total Ther-

mal System Control

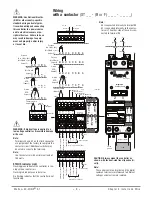

The EZ-ZONE ST solid-state controller offers com-

plete thermal system control in a single package

while reducing system complexity and the cost of

control-loop ownership. You can order a PID control-

ler already connected to a high-amperage, solid-state

relay capable of zero cross or phase angle firing with

the option of adding a properly sized heat sink, an

over-under temperature limit, a shut-down power

contactor, and digital communications in one package.

It just got a whole lot easier to solve the thermal

requirements of your system. Because the EZ-ZONE

ST along with the entire family of EZ-ZONE controls

are highly scalable where you pay only for what you

need. So if you are looking for a PID controller with

high amperage outputs, an over-under limit controller

or an integrated controller, the EZ-ZONE ST is the

answer.

Features and Benefits

Back panel or DIN rail mount

• Provides several mounting options

Compact package

• Reduces panel size

Touch-safe package

• IP2X-Touch safe with back of hand

• Increases safety for installers and operators

±0.1 percent temperature accuracy

• Provides efficient and accurate temperature control

Agency approvals:

(with factory-installed

heatsink);

(without factory-installed heat-

sink); CE; RoHS; W.E.E.E.; CSA

• Limit version features FM approval

• Provides third-party recognition

Three-year warranty

• Provides Watlow reliability and product support

Off-the-shelf designed system solution

• Improves system reliability and reduces wiring

• Reduces installation cost

• Eliminates compatibility headaches often encoun-

tered when using many different components and

brands

Profile capability

• Includes ramp and soak with four files and forty

steps

Communications with PLC, PC or HMI

• ST with optional Modbus

®

RTU protocol

• When used with the optional Remote User Inter

face/Gateway (RUI/GTW) the following protocols

are available:

- EIA 232/485 Modbus RTU

- Modbus TCP

- EtherNet/IP

- DeviceNet

- Profibus DP

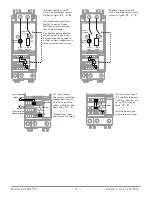

Solid-State Relay output

• Provides faster cycling, more precise control, in-

creased heater life and energy efficiency

• Resistive or inductive load current of up to 75 am-

peres using either zero-cross or phase angle control

modes

• Soft start feature with phase angle control mode to

prevent load failure or blowing fuses

PID temperature control

• Provides accurate temperature control

• Provides a single input and dual outputs

• Provides standard or adaptive (TRU-TUNE+)

PID tuning algorithms.

Optional temperature limit

• Increases safety during under and over-tempera-

ture conditions

Optional definite purpose mechanical contactor

• Enables circuit safety shutdown driven by a limit

controller or a PID alarm output signal

Optional current monitoring feature

• Detects heater current flow and alarm indication of

failed Solid-State Relay or a heater zone

Optional Solid-State Relay heat sink

• Sized and engineered for specific applications

• Factory assembled heat sink required for UL listing

System diagnostics

• Provides continuous system level monitoring with

alerts reducing the overall cost for maintenance ad

service

Advanced controllability algorithms

• TRU-TUNE+™ meets demanding controllability

requirements.

PC Software: EZ-ZONE ST Configurator

• Wizard-style configuration of controller settings

• Online or offline recipe editing

UL® is a registered trademark of Underwriter’s Laboratories Inc.

Modbus™ is a trademark of Schneider Automation Incorporated.