Watlow EZ-ZONE

®

ST

•

67

•

Chapter 7 Features

Time

Temperatur

e

Temperature Reading

from Sensor

Actual Process Temperature

Negative Calibration Offset will

compensate for the difference

between the Sensor Reading and

the Actual Temperature

Calibration

To calibrate an analog input, you will need to provide

two electrical signals or resistance loads near the ex-

tremes of the range that the application is likely to

utilize. See recommended values below:

Sensor Type

Low Source

High Source

thermocouple

0.000 mV

50.000 mV

millivolts

0.000 mV

50.000 mV

volts

0.000V

10.000V

milliamps

0.000 mA

20.000 mA

100 Ω RTD

50.00 Ω

350.00 Ω

1,000 Ω RTD

500.00 Ω

3,500.00 Ω

Follow these steps for a thermocouple or pro-

cess input:

1. Apply the low source signal to the input you are

calibrating. Measure the signal to ensure it is ac-

curate.

2. Read the value of Electrical Measurement

[`Mu]

(Factory Page, Calibration Menu) for that input.

3. Calculate the offset value by subtracting this

value from the low source signal.

4. Set Electrical Input Offset

[ELi;o]

(Factory Page,

Calibration Menu) for this input to the offset value.

5. Check the Electrical Measurement to see whether

it now matches the signal. If it doesn’t match, ad-

just Electrical Input Offset again.

6. Apply the high source signal to the input. Mea-

sure the signal to ensure it is accurate.

7. Read the value of Electrical Measurement for

that input.

8. Calculate the gain value by dividing the low

source signal by this value.

9. Set Electrical Input Slope

[ELi;S]

(Factory Page,

Calibration Menu) for this input to the calculated

gain value.

10. Check the Electrical Measurement to see wheth-

er it now matches the signal. If it doesn’t match,

adjust Electrical Input Slope again.

Set Electrical Input Offset to 0 and Electrical Input

Slope to 1 to restore factory calibration.

Follow these steps for an RTD input:

1. Measure the low source resistance to ensure it is

accurate. Connect the low source resistance to the

input you are calibrating.

2. Read the value of Electrical Measurement

[`Mu]

(Factory Page, Calibration Menu) for that input.

3. Calculate the offset value by subtracting this

value from the low source resistance.

4. Set Electrical Input Offset

[ELi;o]

(Factory Page,

Calibration Menu) for this input to the offset

value.

5. Check the Electrical Measurement to see whether

it now matches the resistance. If it doesn’t match,

adjust Electrical Offset again.

6. Measure the high source resistance to ensure it

is accurate. Connect the high source resistance to

the input.

7. Read the value of Electrical Measurement for

that input.

8. Calculate the gain value by dividing the low

source signal by this value.

9. Set Electrical Input Slope

[ELi;S]

(Factory Page,

Calibration Menu) for this input to the calculated

gain value.

10. Check the Electrical Measurement to see wheth-

er it now matches the signal. If it doesn’t match,

adjust Electrical Input Slope again.

Set Electrical Input Offset to 0 and Electrical Input

Slope to 1 to restore factory calibration.

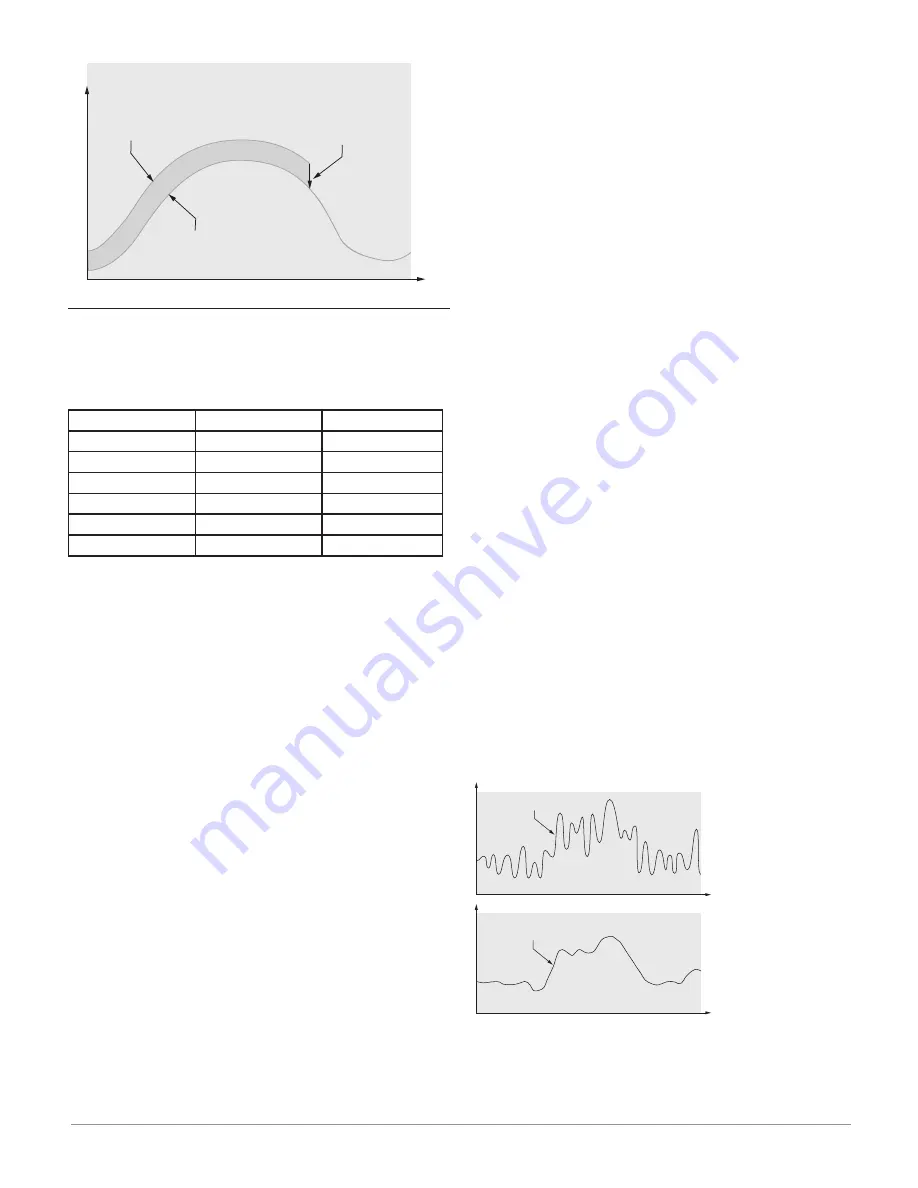

Filter Time Constant

Filtering smoothes an input signal by applying a first-

order filter time constant to the signal. Filtering the

displayed value makes it easier to monitor. Filtering

the signal may improve the performance of PID con-

trol in a noisy or very dynamic system.

Adjust the filter time interval with Filter Time

[`FiL]

(Setup Page, Analog Input Menu).

Example: With a filter value of 0.5 seconds, if the

process input value instantly changes from 0 to 100 and

remained at 100, the display will indicate 100 after five

time constants of the filter value or 2.5 seconds.

Filter Time Constant

Unfiltered Input Signal

Time

Temperature

Filtered Input Signal

Time

Temperature

Sensor Selection

You need to configure the controller to match the in-

put device, which is normally a thermocouple, RTD or

process transmitter.