Wa t l o w E Z - Z O N E

®

P M I n t e g r a t e d C o n t r o l l e r

•

2 3

•

C h a p t e r 2 I n s t a l l a n d W i r e

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to elec-

trical sensors or peripheral

devices. Failure to do so may

result in damage to equip-

ment and property, and/or

injury or loss of life.

Note:

Maximum wire size termina-

tion and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termi-

nation or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be

labeled differently, depend-

ing on the model number.

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digi-

tal input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

Note:

The control output common

terminal and the digital com-

mon terminal are referenced

to different voltages and

must remain isolated.

- A

+ B

com

98

99

CF

CD

CE

B5

D6

D5

power

98

99

CF

CD

CE

- A

+ B

common

power

power

supply

- A

+ B

common

power

power

power

power

RUI/Gateway

EZKB-_ A _ _- _ _ _ _

EZ-ZONE

®

PM

EZ-ZONE

®

ST

ST_ _ - (B or F) _

A

_ -_ _ _ _

98

99

CF

CD

CE

B5

D6

D5

fuse

- A

+ B

com

98

99

CC

CA

CB

B5

D6

D5

power

- A

+ B

common

power

- A

+ B

common

power

power

power

power

PLC

EZ-ZONE

®

PM

EZ-ZONE

®

ST

ST_ _ - (B or F) _

M

_ -_ _ _ _

98

99

CC

CA

CB

B5

D6

D5

power

supply

fuse

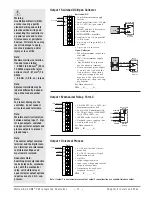

A network using Watlow's Standard Bus

and an RUI/Gateway.

A network using Modbus RTU.

Wiring a Serial EIA-485 Network

Do not route network wires with pow-

er wires. Connect network wires in

daisy-chain fashion when connecting

multiple devices in a network.

A termination resistor may be re-

quired. Place a 120 Ω resistor across

T+/R+ and T-/R- of the last controller

on a network.

Only one protocol per port is avail-

able at a time: either Modbus RTU or

Standard Bus.

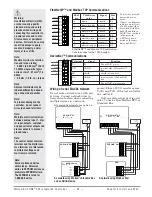

EtherNet/IP™ and Modbus TCP Communications

receive -

unused

E8

E7

E6

E5

E4

E3

E2

E1

Slot B

unused

unused

unused

r

transmit -

tr

RJ-45

pin

T568B wire

color

Signal

Slot

B

8

brown

unused

E8

7

brown & white

unused

E7

6

green

receive -

E6

5

white & blue

unused

E5

4

blue

unused

E4

3

white & green

r

E3

2

orange

transmit -

E2

1

white & orange

tr

E1

EtherNet/IP™ and Modbus TCP communica-

tions to connect with a 10/100 switch.

• Do not route network

wires with power

wires.

• Connect one Ethernet

cable per controller to

a 10/100 mbps ether-

net switch. Both Mod-

bus TCP and Ether-

Net/IP™ are available

on the network.

• A RUI may be con-

nected at the same

time using Slot C.

Note:

Avoid continuous writes

within loops. Excessive

writes to EEPROM will cause

premature EEPROM failure.

The EEPROM is rated for

1,000,000 writes.

Terminal

Signal

Function

V+

V+

DeviceNet™ power

CH

CAN_H

positive side of DeviceNet™

bus

SH

shield

shield interconnect

CL

CAN_L

negative side of DeviceNet™

bus

V-

V-

DeviceNet™ power return

DeviceNet™ Communications

CAN_L

V-

V+

CH

SH

CL

V-

T2

S2

R2

Slot B

V+

CAN_H

shield

Summary of Contents for Integrated Controller Rev C EZ-ZONE PM

Page 79: ......