9

Good pump installation practice

9.1

General recommendations

It is recommended that the pump is sited on a flat, horizontal, rigid surface, free from excessive

vibration, to ensure the correct lubrication of the gearbox and correct pumphead operation. Allow a

free flow of air around the pump to ensure that heat can be dissipated. Ensure that the ambient

temperature around the pump does not exceed the recommended maximum operating temperature.

The STOP key on pumps supplied with a keypad will always stop the pump. However, it is recommended

that a suitable local emergency stop device is fitted into the mains supply to the pump.

Do not stack the pumps more than the recommended maximum number. When the pumps are

stacked, ensure that the ambient temperature around all the pumps in the stack does not exceed the

recommended maximum operating temperature.

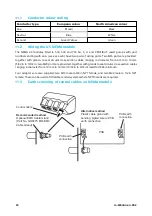

The pump may be set up so that the direction of rotor rotation is clockwise or counter-clockwise,

whichever is convenient.

Please note, however, that for some pumpheads the tube life will be greater if the rotor rotates

clockwise; and that performance against pressure will be maximised if the rotor rotates counter-

clockwise. To achieve pressure in some pumpheads the pump must rotate counter-clockwise.

Optimum

tube life

Maximum

pressure

Peristaltic pumps are self-priming and self-sealing against backflow. No valves are required in inlet or

discharge line, except those specified as below.

Users must fit a non-return valve between the pump and the discharge

pipework to avoid the sudden release of pressurised fluid in the event of a

pumphead or tube failure. This shall be fitted immediately after the

discharge of the pump.

Valves in the process flow must be opened before the pump operates. Users are advised to fit a pressure

relief device between the pump and any valve on the discharge side of the pump to protect against

damage caused by accidental operation with the discharge valve closed.

m-630dun-en-08.2

15

Summary of Contents for 630 Du

Page 81: ...m 630dun en 08 2 81 ...