14

the slots so that the centerline of the hinges are flush with

the leading edge. If the hinges cannot be inserted deeply

enough, use a modeling knife to carefully cut the hinge

slots deeper.

❑

4)

With each of the hinges centered, apply 3-4 drops

of Kwik Bond Thin C/A to the joint where the hinges and

the elevator meet. Allow a few seconds between drops

for the C/A to wick into the hinges, then turn the elevator

over and repeat this procedure on the other side. Let the

C/A dry for about 10 minutes before proceeding. See

photo # 14 below.

❑

5)

Slide the elevator and its hinges into the precut

hinge slots in the trailing edge of the stabilizer. Adjust

the elevator so that the tips of the elevator are even with

the tips of the stabilizer.

❑

6)

While holding the elevator tight against the sta-

bilizer, rotate the elevator down about 45º. Apply 3-4

drops of Kwik Bond Thin C/A to the exposed area of each

hinge. Turn the fuselage over and repeat for the other

side of the hinges. Allow the C/A to dry for about 10

minutes. Once the C/A dries, the elevator may be stiff

and difficult to move. This is normal. Gently move it up

and down about five to ten times to free it up.

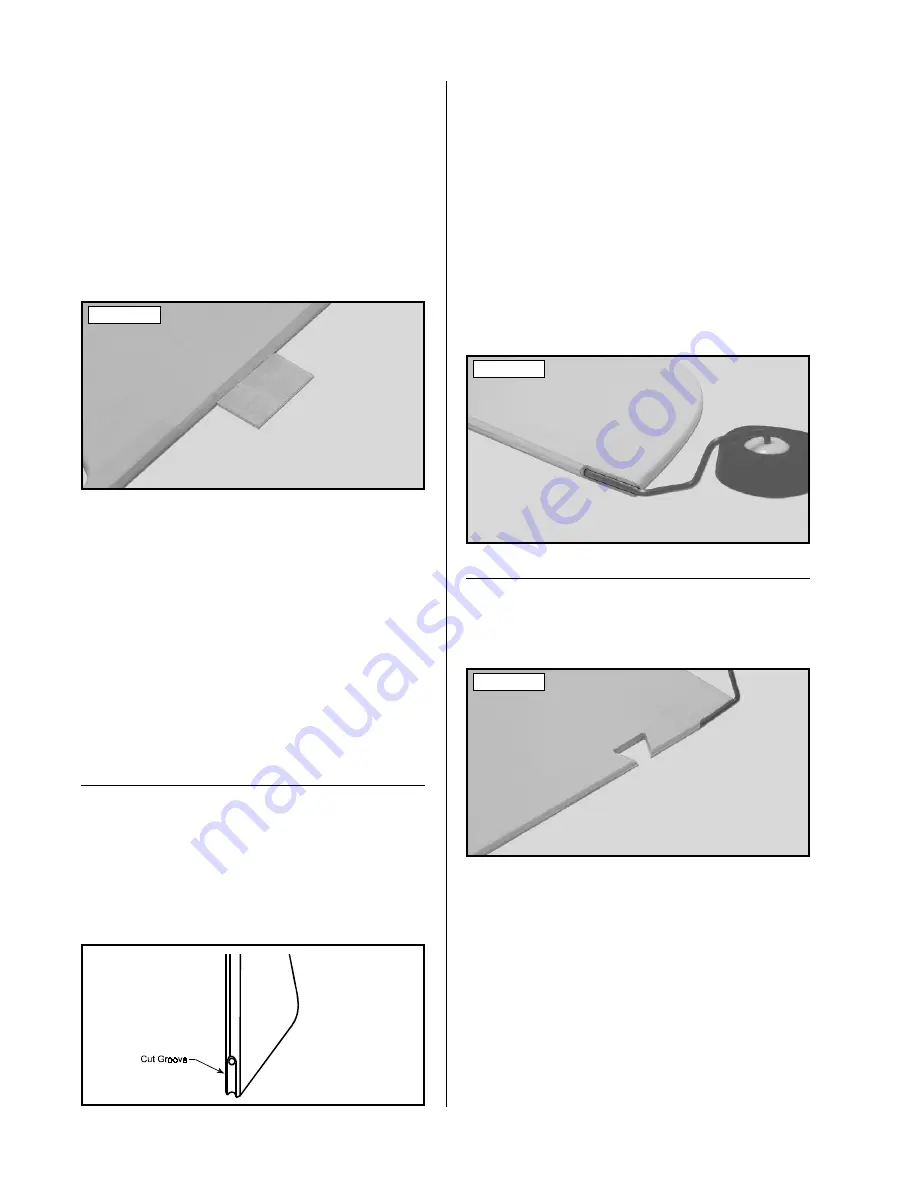

Photo # 14

❑

7)

Using a modeling knife, remove the covering

from over the predrilled hole in the leading edge of the

rudder. The hole is 1/16" in diameter and is located 1/2"

up from the bottom of the rudder.

❑

8)

Using a modeling knife, carefully cut a shallow

groove in the leading edge from the base of the hole down

to the bottom of the rudder. See figure # 6 below.

INSTALLING THE

TAIL WHEEL ASSEMBLY

Figure # 6

❑

9)

Test fit the tail wheel wire into the hole and

groove. When properly aligned, the wire should rest

within the groove and the outer surface of the wire should

be flush with the leading edge of the rudder.

❑

10) When satisfied with the fit, remove the tail wheel

wire. Using 220 grit sandpaper, carefully roughen the

gluing surface of the wire.

❑

11)

Mix a small quantity of Kwik Bond 5 Minute

Epoxy. Pack epoxy into the hole and the groove and

push the tail wheel wire firmly into place. Remove any

excess epoxy using a paper towel and rubbing alcohol.

Allow the epoxy to fully cure before proceeding. See

photo # 15 below.

Photo # 15

HINGING THE RUDDER

❑

12) Using a modeling knife, carefully remove the

covering from over the precut notch in the leading edge

of the rudder. The notch is located 1-1/4" up from the

bottom of the rudder. See photo # 16 below.

❑

13) Locate the two precut hinge slots in the trailing

edge of the vertical stabilizer and the leading edge of the

rudder.

❑

14) Using a modeling knife, carefully remove any

excess covering material from over each of the slots.

❑

15) Test fit the C/A hinges into the hinge slots in

the rudder. Each hinge should be inserted far enough into

the slots so that the centerline of the hinges are flush with

the leading edge. If the hinges cannot be inserted deeply

enough, use a modeling knife to carefully cut the hinge

slots deeper.

Photo # 16